HAWK Excavator Attachments

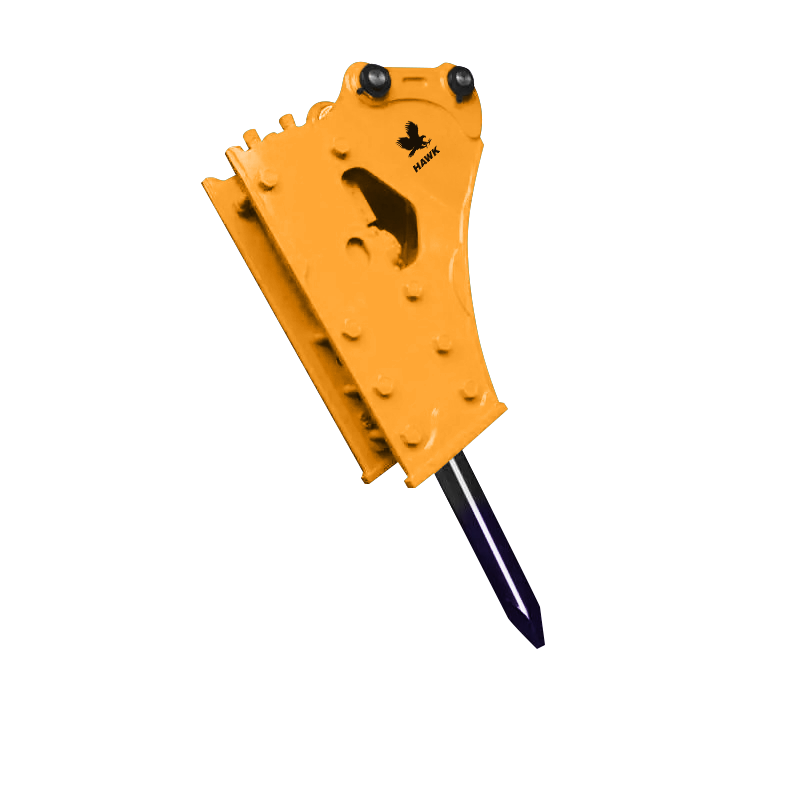

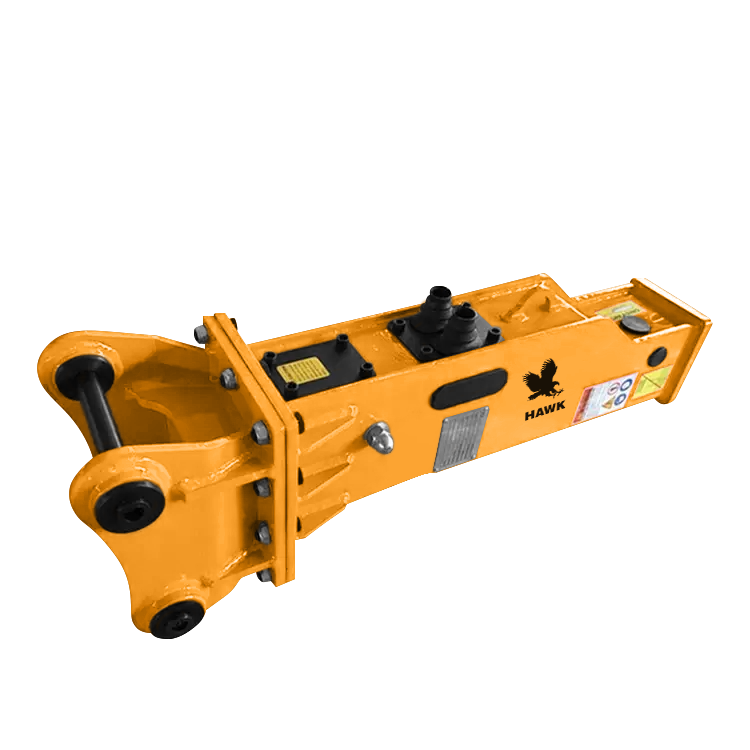

Hydraulic Breaker Hammers

Most contractors prefer using the HAWK Excavator hydraulic breaker hammer because of its high performance in mining, demolitions, excavations, and quarries as it chips away large boulders and concrete structures. They prefer using the hydraulic breaker hammer because of its high performance, and it is also why it is present on most construction sites. The brand’s hydraulic hammer rock breaker reduces manual work, relatively saves energy, and stands to its efficient but straightforward working principle.

General Digging Buckets

Most contractors prefer using the HAWK digger bucket excavator because of its high performance in mining, demolitions, and it is made for light-duty operations like loading, excavation, and earthmoving gravel, loose rock, sand, and earth. This skid steer digging bucket is also ideal for the large-capacity workload like deep earth digging. The advanced digging bucket adapter and high-strength steel can help you save operation time, thereby improving work efficiency.

Non-Rotating Clamshell Buckets

The clamshell bucket by HAWK excavator is best for dredging and material re-handling. This clamshell bucket is available in three different versions: heavy-duty, standard, and light. Regardless of the versions, these equipment pieces feature a 360-degree sealed rotation. There are also units meant for environmental applications.

Rotating Clamshell Buckets

The HAWK’s excavator clamshell bucket is best for dredging and material re-handling. This clamshell bucket is available in three different versions: heavy-duty, standard, and light. Regardless of the versions, these equipment pieces feature a 360-degree sealed rotation. There are also units meant for environmental applications.

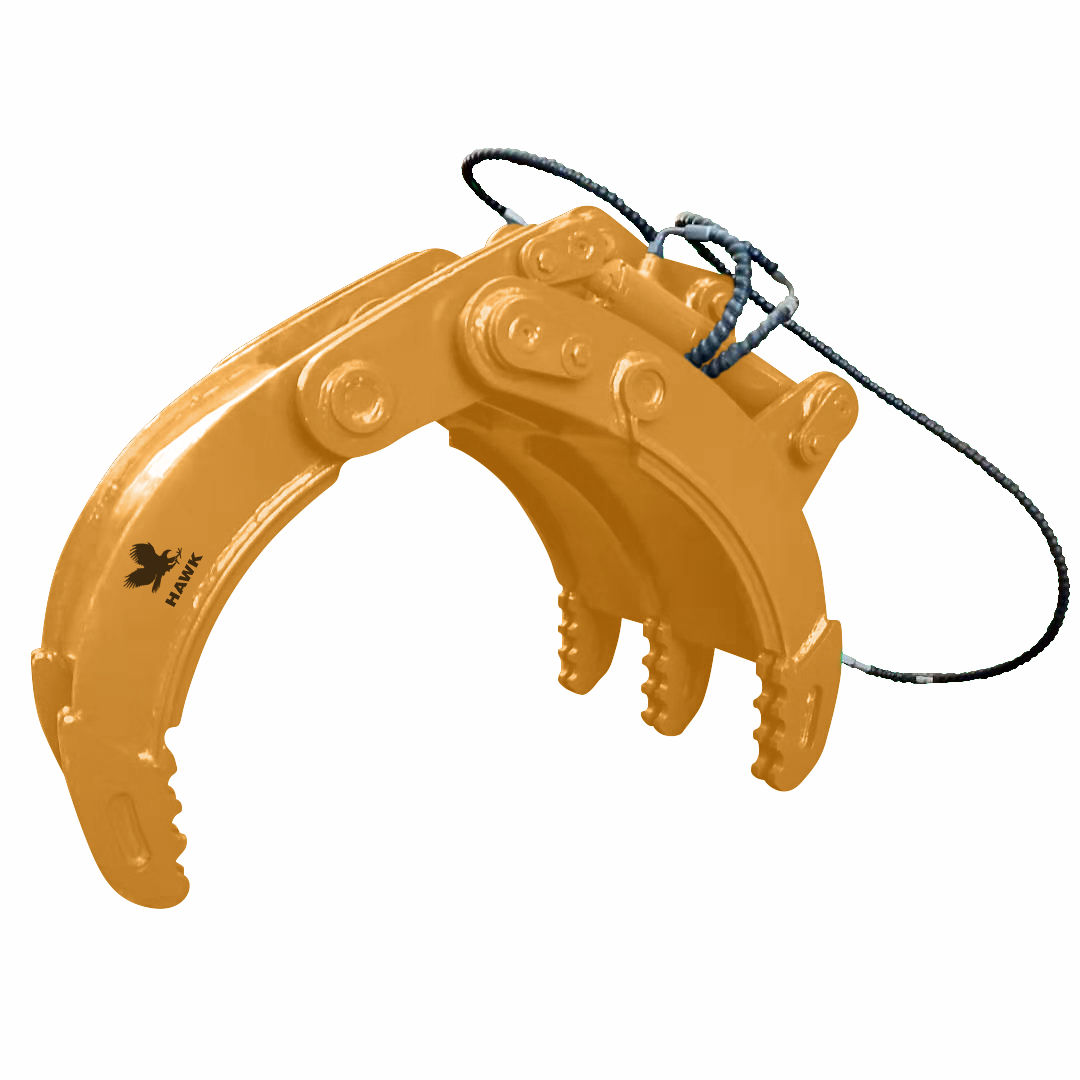

Mechanical Grapples

The mechanical grapple by HAWK excavator is an excellent alternative to excavator buckets, converting the latter into machines fit for demolition site cleanups, sorting trash, and handling loose materials. HAWK offers different sizes and models to match any kind of excavator tasks you have on-site.

Hydraulic Grapples

The HAWK excavator hydraulic grapple for excavator comes with a vast jaw opening quickly, allowing the operator to pick up different larch materials. The hydraulic grapple design also gives a better, firmer grip, making it easy for users to grab uneven loads. With this, they seamlessly improve the efficiency and productivity of loading cycles.

Rotary Hydraulic Grapples

The HAWK excavator takes pride in its excavator hydraulic rotating grapple that’s highly optimized for waste handling, rock moving, and demolition applications. The brand’s 360-degree hydraulic rotating grapple is equipped with a high-quality hydraulic motor system and is made up of high-tensile steel. This results in cheaper operating costs and better productivity.

Demolition Grapples

The Demolition Grapple by HAWK Excavator is a heavy-duty attachment that is commonly used in demolition and construction work. It is typically attached to an excavator or a large piece of construction equipment and is used to grab, lift, and move large pieces of debris, such as concrete, steel, and timber.

A hydraulic hammer, also known as a hydraulic breaker, is a heavy-duty machine used in construction and demolition work to break up hard materials such as concrete, rock, asphalt, and other materials. The hammer is typically mounted on an excavator or other hydraulic machine and is powered by the hydraulic system of the vehicle.

The hydraulic hammer works by using a piston to strike the surface of the material with high impact force, breaking it apart into smaller pieces. The hammer’s chisel or point is placed against the material, and the piston rapidly strikes it, creating a powerful impact that breaks the material. The repeated blows quickly break apart the material, allowing it to be removed or excavated.

Hydraulic hammers are available in a range of sizes and shapes, with different chisel types and lengths, depending on the specific application. They are commonly used in construction, mining, and quarrying operations, as well as in road and bridge repair and demolition work. Hydraulic hammers are designed to be durable and reliable, with a long service life, making them an essential tool for many construction and demolition projects.

Reach Beyond, with HAWK.

Efficient Excavation saves YOU money.

Rent Equipment Shown. The Only place to Rent Long Reach Fronts