Home / Grapples / Rotating Hydraulic /

Case CX210 Rotating Hydraulic Grapple | CASECX210-RHG200

Enhance the efficiency and versatility of your excavator with our Case CX210 Rotating Hydraulic Grapple Attachment. This robust and reliable attachment is engineered to tackle a wide range of material handling tasks with ease and precision.

Equipped with hydraulic-powered jaws, the rotary grapple attachment allows for effortless gripping and lifting of various materials, including logs, rocks, debris, and more. The 360-degree rotation feature enables precise positioning and maneuverability, allowing you to access materials from any angle with ease.

Installation of the rotating hydraulic grapple attachment is quick and straightforward, thanks to its compatibility with the Case CX210 excavator’s coupler system. Once mounted, intuitive hydraulic controls provide operators with smooth and responsive handling, maximizing productivity on the job site.

Built to withstand the rigors of heavy-duty use, our Case CX210 Rotary Hydraulic Grapple Attachment is constructed from high-quality materials and components. Its rugged design ensures reliable operation and long-term durability, even in the most demanding work conditions.

Whether you’re loading trucks, sorting materials, or handling debris, the Case CX210 Rotating Hydraulic Grapple Attachment is the perfect addition to your excavator arsenal.

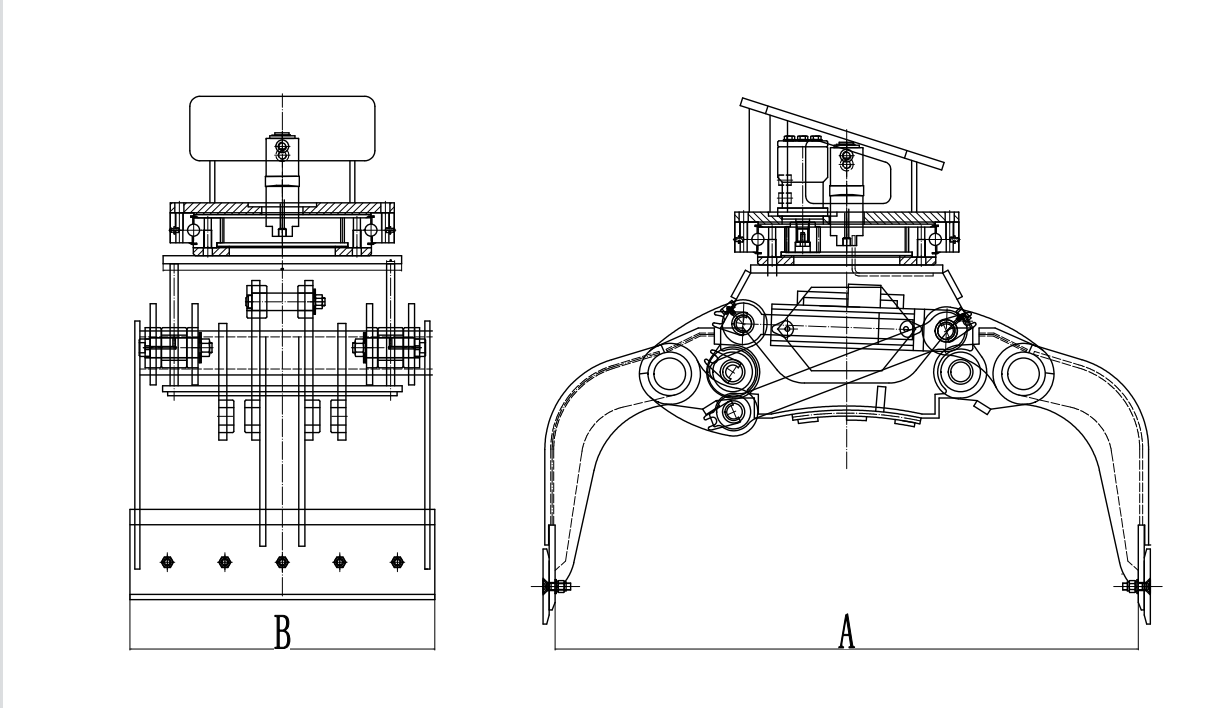

Specifications:

Model: Case CX210-RHG200

Equipment: 20-28T

Material: Q355+NM400

Max Opening: 90.6″ in (2300 mm)

Operating Pressure: .23 – .26 psi (160-180 Kg/m2)

Set Up Pressure: .28 psi (200 Kg/m2)

Operating Flux: 26.4 – 37 GPM (100-140 L/Min)

Weight: 3086.5 lbs (1400 kg)

Excavator Compatibility: Case CX210

In order to achieve a more perfect fit, HAWK can customize the size according to the needs of customers.

Benefits of Case CX210 Rotating Hydraulic Grapple

Versatile Material Handling: With the Case CX210 Rotating Hydraulic Grapple Attachment, you gain unparalleled versatility in material handling. From logs and rocks to debris and waste, this attachment enables efficient and precise handling of a wide range of materials, enhancing your productivity across various job sites.

360-Degree Rotation: One of the key benefits of the Case CX210 Rotating Hydraulic Grapple Attachment is its 360-degree rotation capability. This feature enables you to access materials from any angle, making it easier to position and maneuver objects with precision, even in tight or awkward spaces.

Enhanced Efficiency: The hydraulic-powered jaws of the rotating grapple attachment ensure swift and effortless gripping and lifting of materials. This translates to increased efficiency and reduced downtime, allowing you to accomplish more in less time and with minimal effort.

Increased Safety: By minimizing the need for manual handling of materials, the rotating grapple attachment helps improve safety on the job site. Operators can handle materials from a safe distance, reducing the risk of accidents and injuries associated with manual lifting and handling.

Easy Installation and Operation: Installing and operating the Case CX210 Rotating Hydraulic Grapple Attachment is a breeze. Its compatibility with the excavator’s coupler system ensures quick and hassle-free installation, while intuitive hydraulic controls offer smooth and responsive operation, enhancing user experience and productivity.

Cost-Effective Solution: Investing in the Case CX210 Rotating Hydraulic Grapple Attachment is a cost-effective solution for your material handling needs. Its versatility, efficiency, and durability result in long-term cost savings by streamlining operations, minimizing downtime, and maximizing productivity.

Features of the Case CX210 Rotating Hydraulic Grapple

Frequently Asked Questions – Case CX210 Rotating Hydraulic Grapple

What is a rotary hydraulic grapple attachment, and how does it work?

A rotary hydraulic grapple attachment is a versatile tool designed to enhance excavators’ material handling capabilities. It features hydraulic-powered jaws that can open and close to grip various materials such as rocks, logs, and debris. The attachment’s 360-degree rotation capability allows for precise positioning and handling from any angle.

How do I install the Komatsu PC210 Rotating Hydraulic Grapple Attachment on my excavator?

Installation of the Case CX210 Rotating Hydraulic Grapple Attachment typically involves connecting it to the excavator’s quick coupler system. Detailed installation instructions are provided by the manufacturer and should be followed carefully to ensure proper attachment and alignment.

What maintenance is required for a rotating hydraulic grapple attachment?

Regular maintenance is essential to ensure the optimal performance and longevity of a rotating hydraulic grapple attachment. This may include routine inspections, lubrication of moving parts, checking hydraulic fluid levels, and replacing worn or damaged components as needed. Following the manufacturer’s maintenance recommendations is crucial to prevent downtime and ensure safe operation.

Can a rotating hydraulic grapple attachment be used underwater?

While rotating hydraulic grapple attachments are designed for use in various environments, including wet conditions, it’s essential to consider the specific requirements and limitations of the attachment and excavator. Consult the manufacturer’s guidelines and safety recommendations to determine if the attachment is suitable for underwater use and take necessary precautions to ensure safe operation.

What safety features are included in the Case CX210 Rotating Hydraulic Grapple Attachment?

The Case CX210 Rotating Hydraulic Grapple Attachment is equipped with various safety features to ensure operator safety during operation. These may include protective guards, safety locks, and emergency stop mechanisms to prevent accidents and injuries.