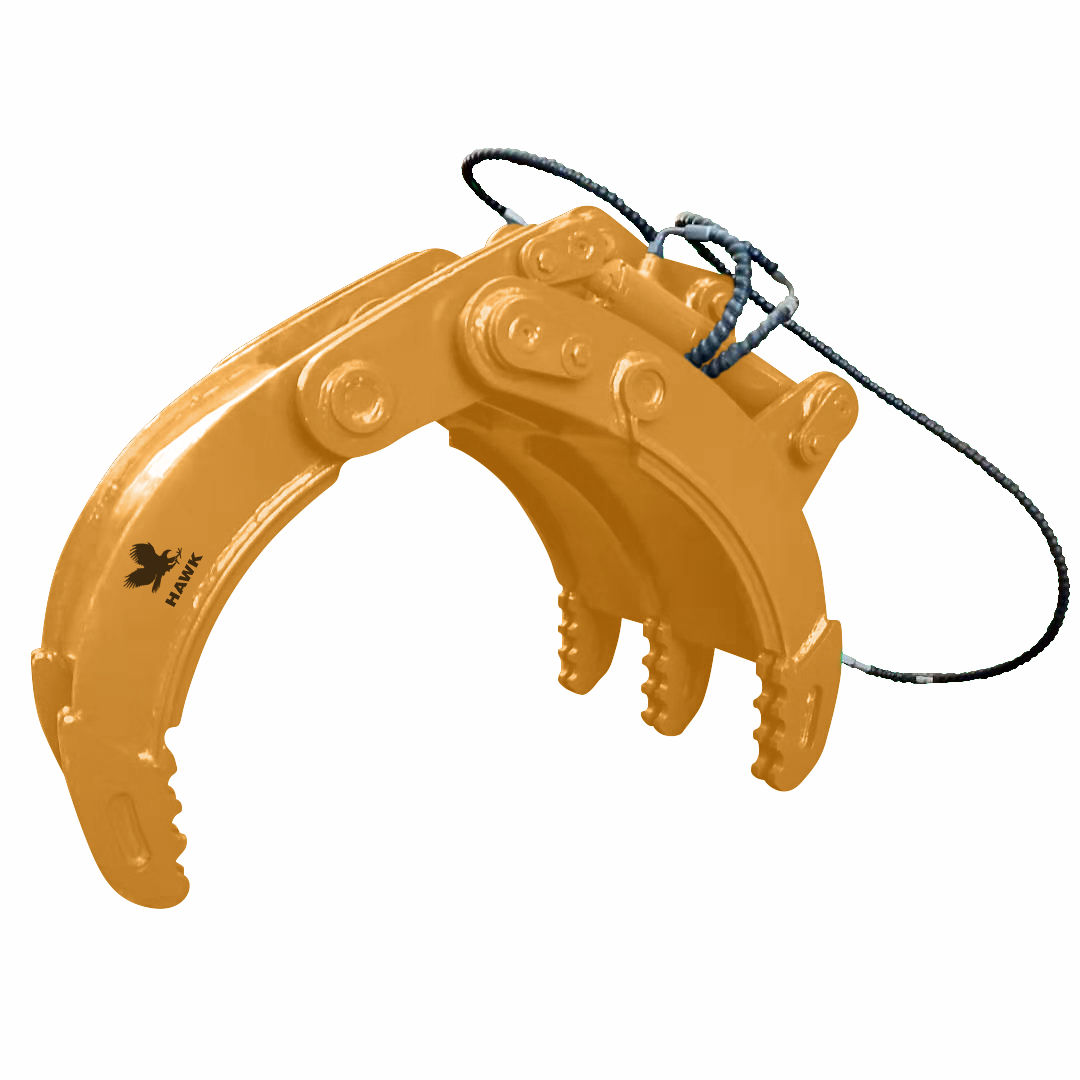

Hydraulic Grapples

Hawk Excavator hydraulic grapples feature heavy-duty construction, ensuring durability and reliability in the most demanding work environments. Built to withstand the rigors of daily operation, these attachments are made from high-quality materials that are capable of withstanding the toughest conditions.

Equipped with powerful hydraulic cylinders, our grapples offer smooth and precise operation, allowing operators to easily maneuver and position materials with accuracy. The hydraulic functionality provides exceptional gripping force, ensuring secure handling of various loads.

The wide jaw opening of our hydraulic grapples allows for efficient loading and unloading of materials, maximizing productivity and reducing cycle times. Whether handling logs, rocks, debris, or other materials, our grapples provide a secure grip for safe and efficient material handling.

Installation and setup are quick and straightforward, allowing you to attach the hydraulic grapple to your excavator in no time. Minimal downtime means you can get back to work faster, increasing overall efficiency and productivity on the job site.

Finished with a durable coating, our hydraulic grapples are resistant to corrosion and wear, ensuring long-lasting performance even in harsh operating conditions. With optional features and accessories available, you can further customize your grapple to suit your individual needs and preferences.

Product Specifications

Model | Excavator Weight | Opening | Operating Weight | Operating Flux | Operating Pressure |

|---|---|---|---|---|---|

1-2 Tons | 25.6 in (650 mm) | 242.5 lbs. (400 kg) | 13.2-21 GPM (50-80 L/min) | 2320.6 PSI (160 Bar) | |

3-4 Tons | 28.3 in (720 mm) | 407.9 lbs (185 kg) | 13.2-21 GPM (50-80 L/min) | 2320.6 PSI (160 Bar) | |

5-6 Tons | 34.6 in (880 mm) | 639.3 lbs. (290 kg) | 15.9-21.1 GPM (50-80 L/min) | 2320.6 PSI (160 Bar) | |

8-11 Tons | 37.8 in (960 mm) | 859.8 lbs (390 kg) | 18.5-26.4 GPM (70-100 L/min) | 2900.8 PSI (200 Bar) | |

12-18 Tons | 47.6 in (1210 mm) | 1873.6 lbs (850 kg) | 31.7-47.6 GPM (120-180 L/min) | 3335.9 PSI (230 Bar) | |

20-24 Tons | 55.9 in (1420 mm) | 2623.5 lbs. (1190 kg) | 39.6-58.1 GPM (150-220 L/min) | 3335.9 PSI (230 Bar) | |

25-28 Tons | 66.1 in (1680 mm) | 3527.4 lbs (1600 kg) | 42.3-63.4 GPM (160-240 L/Min) | 3625.9 PSI (250 Bar) | |

30-34 Tons | 66.1 in (1680 mm) | 3637.6 lbs (1650 kg) | 52.8-79.3 GPM (200-300 L/Min) | 3196 PSI (270 Bar) | |

35-38 Tons | 89 in (2260 mm) | 4166.7 lbs (1890 kg) | 68.7-95.1 GPM (260-360 L/min) | 3196 PSI (270 Bar) | |

30-45 Tons | 92.1 in (2340 mm) | 5291.1 lbs. (2400 kg) | 68.7-95.1 GPM (260-360 L/min) | 3196 PSI (270 Bar) |

HAWK Hydraulic Grapples

Manufacturer | Model | Opening | Weight |

|---|---|---|---|

Case | 55.9 in (1420mm) | 2623.5 lbs (1190kg) | |

Caterpillar | 55.9 in (1420mm) | 2623.5 lbs (1190kg) | |

Caterpillar | 66.1 in (1680mm) | 3527.4 lbs (1600kg) | |

Caterpillar | 89 in (2260mm) | 4166.7 lbs (1890kg) | |

Hitachi | 47.6 in (1210mm) | 1873.9 lbs (850kg) | |

John Deere | 55.9 in (1420mm) | 2623.5 lbs (1190kg) | |

John Deere | 55.9 in (1420mm) | 2623.5 lbs (1190kg) | |

John Deere | 55.9 in (1420mm) | 2623.5 lbs (1190kg) | |

John Deere | 89 in (2260mm) | 4166.7 lbs (1890kg) | |

Komatsu | 55.9 in (1420mm) | 2623.5 lbs (1190 | |

Komatsu | 89 in (2260mm) | 4166.7 lbs (1890kg) | |

Komatsu | 92.1 in (2340mm) | 5291.1 lbs (2400kg) |

Benefits of Hydraulic Grapples

Hydraulic grapples offer several benefits for construction, demolition, and mining applications. These benefits include:

Enhanced Efficiency: Our hydraulic grapples are designed to streamline material handling tasks, increasing efficiency and reducing manual labor. With their powerful hydraulic functionality and precise operation, these attachments allow operators to complete tasks quickly and effectively.

Versatility in Application: From forestry and landscaping to demolition and construction, our hydraulic grapples are versatile attachments suitable for a wide range of applications. Whether you need to lift logs, rocks, debris, or other materials, our grapples provide a secure grip and reliable performance in various work environments.

Improved Safety: Safety is paramount in any work environment, and our hydraulic grapples are engineered with safety in mind. With their secure grip and precise control, operators can handle materials with confidence, reducing the risk of accidents and injuries on the job site.

Durable Construction: Built to withstand the rigors of heavy-duty use, our hydraulic grapples are constructed from high-quality materials for long-lasting durability and reliability. With proper maintenance, these attachments can withstand the toughest conditions and provide years of dependable service.

Quick and Easy Installation: Installing our hydraulic grapples onto your excavator is quick and straightforward, allowing you to get to work faster. Minimal downtime means you can maximize uptime and keep your projects on schedule.

Customizable Options: With interchangeable jaws and optional features available, our hydraulic grapples can be customized to suit your specific needs and preferences. Whether you need a wider jaw opening or specialized functionality, we offer a range of options to meet your requirements.

Cost-Effective Solution: Investing in a hydraulic grapple can help you save time and money on labor costs, as well as improve overall efficiency on the job site. With their ability to handle a wide range of materials and tasks, these attachments offer a cost-effective solution for your material handling needs.

Features of Hydraulic Grapples

Versatile Attachment Compatibility:

Our hydraulic grapples are designed to be compatible with a wide range of excavators, ensuring versatility and adaptability across various equipment models and sizes.

Heavy-Duty Construction:

Constructed from high-quality materials, our hydraulic grapples are built to withstand the rigors of demanding work environments. Robust construction ensures durability and long-term reliability, even in the toughest conditions.

Hydraulic Operation:

Equipped with powerful hydraulic cylinders, our grapples offer smooth and efficient operation. Hydraulic functionality allows for precise control over the grapple’s movements, enhancing productivity and ease of use.

360-Degree Rotation:

Some models feature a 360-degree rotation capability, providing enhanced maneuverability and flexibility on the job site. The ability to rotate the grapple allows operators to easily position and handle materials from various angles.

Wide Jaw Opening:

Our hydraulic grapples feature a wide jaw opening, enabling them to effectively grasp and handle large volumes of material. The generous opening size ensures efficient loading and unloading operations, maximizing productivity.

Easy Installation and Setup:

Designed for hassle-free installation and setup, our hydraulic grapples can be quickly attached to excavators without the need for extensive modifications. Easy installation ensures minimal downtime and maximum productivity on the job site.

Durable Finish:

Finished with a durable coating, our hydraulic grapples are resistant to corrosion and wear, ensuring longevity and low maintenance requirements. The protective finish helps to extend the lifespan of the grapple, even in harsh operating conditions.

Frequently Asked Questions

What is a hydraulic grapple?

A hydraulic grapple is a specialized attachment for excavators and other heavy equipment, designed to efficiently handle various materials by utilizing hydraulic power. It typically consists of jaws or claws operated by hydraulic cylinders to grip and lift objects.

How does a hydraulic grapple work?

Hydraulic grapples operate using the hydraulic system of the excavator. The hydraulic cylinders control the movement of the grapple’s jaws or claws, allowing the operator to open, close, and manipulate the grapple to securely grip and lift materials.

What types of materials can a hydraulic grapple handle?

Hydraulic grapples are capable of handling a wide range of materials, including rocks, logs, debris, scrap metal, and more. Their versatile design allows them to securely grip and lift various shapes and sizes of materials encountered on construction, demolition, and forestry sites.

What maintenance is required for a hydraulic grapple?

Maintenance requirements for hydraulic grapples typically include regular inspection of hydraulic hoses and fittings, lubrication of moving parts, and occasional replacement of wear components such as teeth or blades. Proper maintenance helps ensure optimal performance and longevity of the grapple.

Are there safety features integrated into hydraulic grapples?

Many hydraulic grapples are equipped with safety features to ensure operator and worksite safety. These may include overload protection systems, pressure relief valves, and secure locking mechanisms to prevent accidents and equipment damage.

Can a hydraulic grapple be customized for specific applications?

Yes, some manufacturers offer customization options for hydraulic grapples to tailor them to specific application requirements. This may include adjustments to jaw configurations, size variations, and additional features to optimize performance for unique job site needs