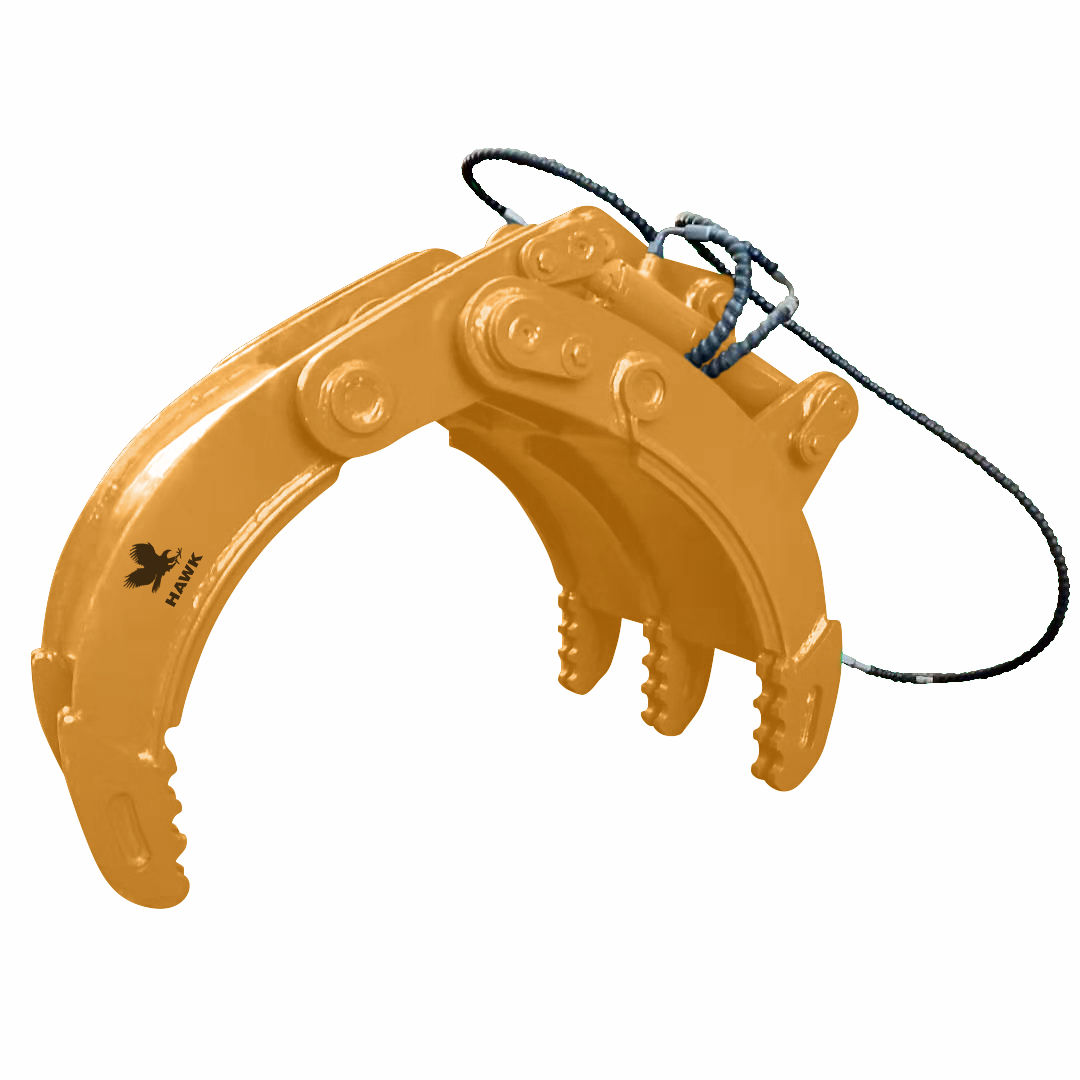

Hydraulic Grapple – HG200

HAWK Excavator HG200 hydraulic grapple series stands out as a natural performer in dredging and material re-handling tasks and caters to a wide range of operational needs. Its precision grip and high level maneuverability ensure your tasks are completed quickly and effectively.

HAWK’s HG200 hydraulic grapple is built for Excavators up to 24 tons and is renowned for its efficiency, durability, and quality. Customers can customize their equipment based on various parameters, ensuring optimal performance and operational compatibility.

Excavator Range: 20-24 Ton

Working Conditions: Use in operations like excavation and loading of earth, sand, and loose materials.

Product Specifications

Model: HG200

Max Opening: 55.9 in (1420 mm)

Operating Flux: 39.6 – 58.1 GPM (150-220 L/Min)

Operating Pressure: 3335.9 PSI (230 Bar)

Weight: 2623.5 lbs (1190 kg)

Material: Q355+NM400

Applications:

- Mining

- Demolition

- Construction

- Quarry

- Skid steer loader

- Backhoe loader

- Crane

- Telescopic handler

- Wheel loader

- Excavator

Benefits of Hydraulic Grapples

Hydraulic non-rotating grapples like the Hawk Excavator HG200 offer a multitude of benefits, catering to various industrial and construction needs. Here’s why they stand out:

Enhanced Stability: With a fixed orientation, hydraulic non-rotating grapples provide unparalleled stability during material handling tasks. This ensures precise control and reduces the risk of accidents, especially in challenging terrain.

Optimized Gripping Power: Designed with robust hydraulic systems, these grapples deliver exceptional gripping power to securely hold onto materials of varying shapes and sizes. Whether it’s bulky debris, logs, or scrap metal, these grapples ensure a firm grip for efficient handling.

Increased Productivity: By streamlining material handling processes, hydraulic non-rotating grapples contribute to significant improvements in productivity. Their swift and precise operation allows operators to complete tasks swiftly, resulting in faster project turnaround times.

Versatility in Application: From demolition and land clearing to waste management and recycling, hydraulic non-rotating grapples excel in diverse applications. Their adaptability makes them indispensable tools across industries, offering unmatched versatility on the job site.

Durability and Longevity: Constructed from high-quality materials and engineered to withstand rigorous use, these grapples boast exceptional durability and longevity. They are built to endure harsh operating conditions, ensuring reliable performance over an extended lifespan.

Reduced Maintenance Needs: With fewer moving parts compared to rotating grapples, hydraulic non-rotating grapples require minimal maintenance. This translates to lower downtime and reduced maintenance costs, allowing businesses to maximize operational efficiency.

Operator Comfort and Safety: Equipped with intuitive controls and ergonomic design features, hydraulic non-rotating grapples prioritize operator comfort and safety. Operators can maneuver the grapple with ease, reducing fatigue and promoting safe handling practices on the job site.

Environmental Considerations: With efficient material handling capabilities, these grapples contribute to environmentally responsible practices by minimizing material wastage and optimizing resource utilization. This aligns with sustainability goals and regulatory requirements, fostering eco-friendly operations.

Customization Options: Hydraulic non-rotating grapples can be tailored to meet specific job site requirements and equipment specifications. Whether it’s adjusting the jaw configuration or incorporating additional features, customization options ensure optimal performance and compatibility.

Cost-Effective Solution: Investing in hydraulic non-rotating grapples represents a cost-effective solution for material handling needs. Their efficient operation, durability, and versatility offer long-term value, delivering a favorable return on investment for businesses of all sizes.

Features of Hydraulic Grapples – HG200

Discover the remarkable features of the HG200 hydraulic grapple, meticulously engineered to excel in demanding material handling applications:

Fixed Jaw Design: Our hydraulic non-rotating grapples feature a fixed jaw design, providing exceptional stability and control during material handling operations. This design ensures precise gripping without the need for rotational movement, enhancing efficiency on the job site.

High-Quality Hydraulic System: Equipped with a high-quality hydraulic system, our grapples deliver superior performance and reliability. The hydraulics enable smooth and responsive operation, allowing operators to handle materials with ease and precision.

Heavy-Duty Construction: Crafted from rugged materials and built to withstand the rigors of heavy-duty applications, our hydraulic non-rotating grapples are engineered for durability and longevity. The robust construction ensures reliable performance in challenging environments.

Versatile Jaw Configuration: Our grapples offer versatile jaw configurations to accommodate various materials and job site requirements. Whether handling logs, debris, or scrap metal, operators can customize the jaw settings for optimal gripping performance.

Integrated Cylinder Protection: Designed with integrated cylinder protection, our grapples safeguard hydraulic cylinders from damage during operation. This feature enhances the longevity of the grapple and minimizes maintenance requirements, maximizing uptime and productivity.

Easy Installation and Compatibility: With a user-friendly design and universal compatibility, our hydraulic non-rotating grapples are easy to install and integrate with a wide range of excavators. This ensures seamless integration into existing equipment fleets, minimizing downtime and maximizing efficiency.

Safety Features: Prioritizing operator safety, our grapples are equipped with safety features such as load-holding valves and reinforced components. These safety measures enhance operator confidence and mitigate the risk of accidents on the job site.

Optimized Weight Distribution: Engineered for optimal weight distribution, our grapples maintain balance and stability during lifting and maneuvering tasks. This ensures smooth and controlled operation, even when handling heavy loads or operating on uneven terrain.

Low Maintenance Requirements: With minimal moving parts and durable components, our hydraulic non-rotating grapples require low maintenance and upkeep. This reduces downtime and maintenance costs, allowing operators to focus on productivity and efficiency.

Enhanced Control and Maneuverability: Featuring intuitive controls and ergonomic design, our grapples offer enhanced control and maneuverability for operators. The ergonomic grip and responsive controls enable precise handling, facilitating efficient material placement and positioning.

Experience the power, precision, and reliability of our hydraulic non-rotating grapples, engineered to exceed expectations and deliver exceptional performance in diverse material handling applications.

Frequently Asked Questions – Hydraulic Grapple HG200

Can the HG200 hydraulic grapple be used for demolition applications?

Yes, the HG200 hydraulic grapple is suitable for demolition applications, allowing operators to efficiently handle and sort demolition debris, concrete, and other materials on the job site.

Do Hawk Excavator hydraulic grapples require any special maintenance?

Hawk Excavator hydraulic grapples are designed for minimal maintenance requirements, with durable components and a robust construction. Regular inspections and greasing of pivot points are recommended to ensure optimal performance and longevity.

How does a hydraulic grapple work?

Hydraulic grapples operate using the hydraulic system of the excavator. The hydraulic cylinders control the movement of the grapple’s jaws or claws, allowing the operator to open, close, and manipulate the grapple to securely grip and lift materials.

Is the HG200 hydraulic grapple easy to install on an excavator?

Yes, the HG200 hydraulic grapple is designed for easy installation and compatibility with various excavator models. Our detailed installation instructions and universal mounting system make the process straightforward for operators and technicians.

What safety features are incorporated into Hawk hydraulic grapples?

Hawk hydraulic grapples are equipped with safety features such as load-holding valves and reinforced components to ensure operator safety during operation. These safety measures help prevent accidents and enhance job site safety.

Can Hawk Excavator hydraulic grapples be used for handling logs and timber?

Yes, Hawk hydraulic grapples are ideal for handling logs, timber, and other forestry materials. Its versatile jaw configuration allows for secure gripping and efficient handling of various shapes and sizes of materials.

Is the HG200 hydraulic grapple suitable for use in harsh environmental conditions?

Yes, the HG200 hydraulic grapple is built to withstand harsh environmental conditions and rugged job site environments. Its durable construction and corrosion-resistant materials ensure reliable performance in challenging conditions.