Komatsu PC210 Excavator

The Komatsu PC210 excavator is a powerful and versatile piece of heavy equipment that is commonly used in construction and mining operations. With a maximum digging depth of 22 feet and a maximum digging reach of 33 feet, this excavator is capable of handling a wide variety of tasks, from digging trenches and foundations to clearing land and demolishing structures. One of the key features of the Komatsu PC210 is its advanced hydraulic system, which provides precise control and smooth operation.

This system allows operators to easily adjust the speed and power of the excavator’s movement, as well as the strength of its digging force. Additionally, the excavator is equipped with a range of attachments, including buckets, hammers, and rippers, which can be quickly and easily swapped out to suit the needs of different jobs.

Despite its large size and heavy-duty capabilities, the Komatsu PC210 is also easy to maneuver and transport. Its compact design and hydrostatic transmission allow it to be moved around tight job sites with ease. Plus, the excavator can be outfitted with either steel or rubber tracks, depending on the needs of the job and the conditions of the site.

KOMATSU PC210 EXCAVATOR ADD-ONS

Long Reach Arms

The HAWK Long Reach Arms Package is an excellent addition to any standard excavator for deep foundation excavation, industrial demolition, deeper or more precise dredging, large digging projects, barge unloading, tank cleaning, and for any.. read more

Amphibious Undercarriage

The HAWK Amphibious Undercarriage is an excavator that you can use in inaccessible places. Install our amphibious undercarriage and tracks package and easily be able to dredge and excavate from land, sea, or swamp,.. read more

RTK GPS Dredge & Dig System

The HAWK RTK GPS Dredge & Dig System is an efficient and accurate dredging equipment and you always know where you’re dredging with our new RTK GPS system that can be attached to a dredge.. read more

KOMATSU PC210 EXCAVATOR ATTACHMENTS

Hydraulic Breaker Hammers

The HAWK hydraulic breaker hammer is essential in mining, demolitions, excavations, and quarries as it chips away large boulders and concrete structures. Most contractors prefer using the hydraulic hammer breaker because of its high performance,.. read more

KPC210-HBH1250T – 5-inch Hydraulic Breaker Hammer (Top)

KPC210-HBH1250S – 5-inch Hydraulic Breaker Hammer (Side)

KPC210-HBH1250B – 5-inch Noise Reducer Box Hydraulic Breaker Hammer (Box)

KPC210-HBH1400T – 5 1/2-inch Hydraulic Breaker Hammer (Top)

KPC210-HBH1400S – 5 1/2-inch Hydraulic Breaker Hammer (Side)

KPC210-HBH1400B – 5 1/2-inch Noise Reducer Hydraulic Breaker Hammer (Box)

General Purpose Buckets

HAWK Excavator general purpose bucket is made for light-duty operations like loading, excavation, and earthmoving gravel, loose rock, sand, and earth. This skid steer digging bucket is also ideal for the large-capacity workload like deep earth.. read more

HAWK Capacity Clamshell Buckets

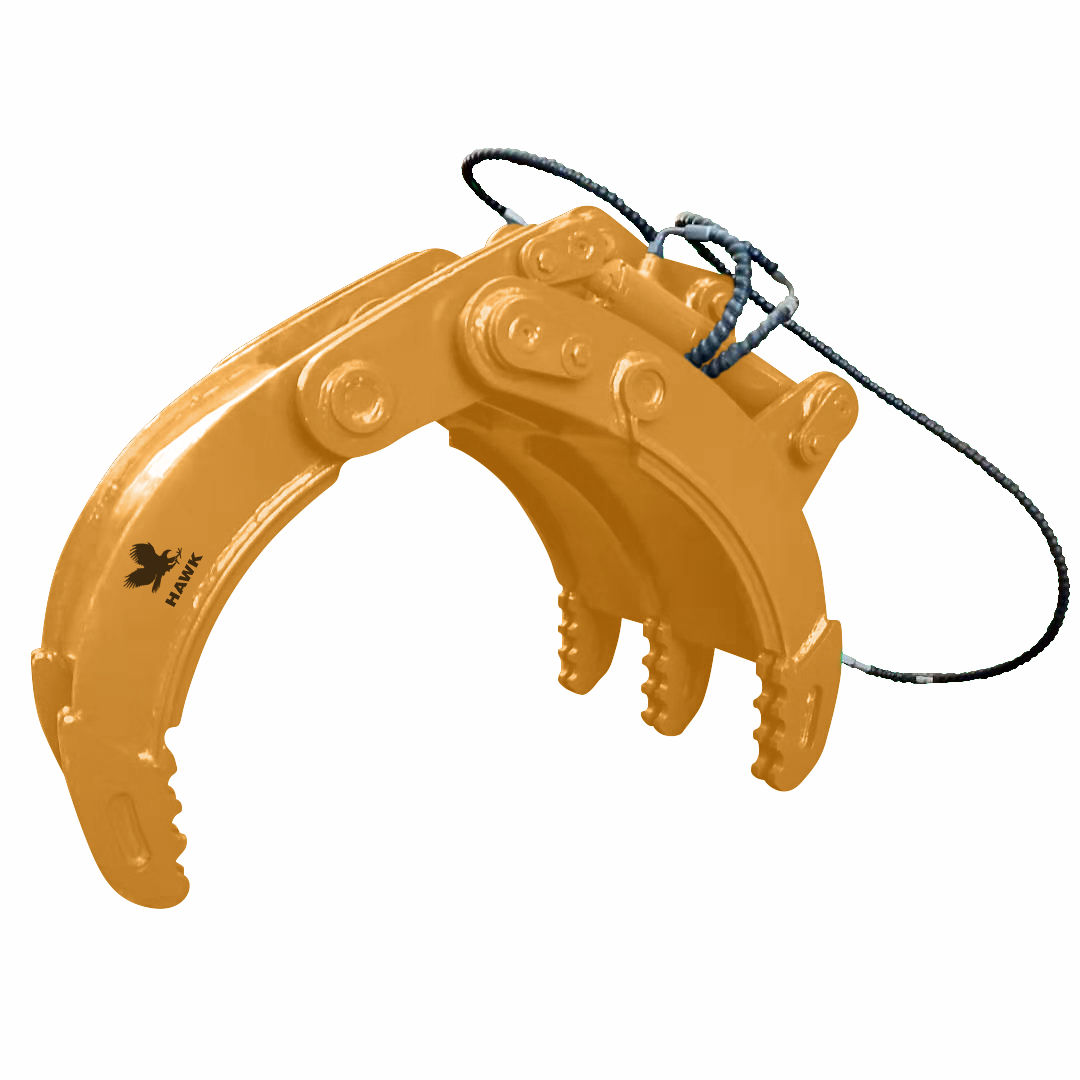

Hydraulic Grapple

HAWK’s hydraulic grapple for excavator comes with a vast jaw opening quickly, allowing the operator to pick up different larch materials. The hydraulic grapple design also gives a better, firmer grip, making it easy for users to grab uneven loads. With this, they seamlessly improve the efficiency and productivity of loading cycles.

KOMATSU PC210 EXCAVATOR PRODUCT FEATURES

Large displacement high efficiency pump

Large displacement hydraulic implement pumps provide high flow output at lower engine RPM, operation at the most efficient engine speed.

Closed-center load-sensing hydraulic system

Smooth operation, quick cycle times, great multi-function, while lowering fuel consumption from closed-center load-sensing hydraulic system.

Komatsu PC210 Excavator is Built for strength

Equipment designed for long-term durability with high resistance to bending and torsional stress. Booms and arms are constructed with thick plates of high tensile strength streel and designed with large cross-sectional areas.

Cleaner emissions

A heavy-duty aftertreatment system that combines a Komatsu Diesel Particulate Filter (KDPF) and selective catalytic reduction (SCR). The system injects the correct amount of diesel exhaust fluid at the proper rate, decomposing nitrogen oxide.

Easy access

Engine oil check and filter locations integrated into one side to allow easier maintenance access.

Advanced ergonomic design

Wide spacious cab includes a heated air suspension seat with reclining backrest. Seat height and position are easily adjusted using a pull-up lever. Armrest position easily adjusted with the console.

Information at your fingertips

Updated, large, high-resolution LCD color monitor to ease accurate and smooth work. Key machine information displayed in user-friendly interface, rearview camera and DEF level gauge display added to default main screen.

Rollover protection

A ROPS cab that conforms to ISO 12117-2 comes as standard equipment. It also satisfies requirements for level 1 operator protective guard (OPG) and top guard (ISO 10262).

Multi-operator productivity

An operator identification ID can be set up for each operator and used to manage operation information of individual machines using Komtrax data. Data can analyze operation status by operator and by machine.

Reduce fuel consumption

Auto idle shutdown automatically shuts the engine down after idling for a set period to reduce unnecessary fuel consumption and exhaust emissions. Time before engine is shutdown can be programmed from 5 to 60 minutes.

Designed for durability

Large heavy-duty revolving frame guards and swivel guard help protect vital components from damage and debris build-up.

Ease of maintenance and serviceability

Provide a convenient and more secure work area in front of the engine. A new step provides easier access for filling the AdBlue/DEF tank.

PRODUCT SPECIFICATIONS FOR KOMATSU PC210 EXCAVATOR

Engine | |

|---|---|

Model | Komatsu SAA6D107E-3* |

Type | Water-cooled, 4-cycle, direct injection |

Aspiration | Komatsu Variable Geometry Turbocharged, aftercooled, cooled EGR |

Number of cylinders | 6 |

Bore | 4.21 in |

Stroke | 4.88 in |

Piston displacement | 408 in³ |

Horsepower | |

ISO 9249 / SAE J1349 – Net | 165 HP |

Fan at maximum speed – Net | 159 HP |

Rated rpm | 2,000 rpm |

Fan drive method for radiator cooling | Mechanical with viscous fan clutch |

Governor | All-speed control, electronic |

*EPA Tier 4 Final emissions certified | |

Hydraulics | |

Type: HydrauMind (Hydraulic Mechanical Intelligence New Design) system, closed-center system with load sensing valves and pressure compensated valves | |

Number of selectable working modes | 6 |

Main pump | |

Type | Variable displacement piston type |

Pumps for | Boom, arm, bucket, swing, and travel circuits |

Maximum flow | 125.5 US gpm |

Supply for control circuit | Self-reducing valve |

Hydraulic motors | |

Travel | 2 x axial piston motors with parking brake |

Swing | 1 x axial piston motor with swing holding brake |

Relief valve setting | |

Implement circuits | 5,400 psi |

Travel circuit | 5,400 psi |

Swing circuit | 4,190 psi |

Pilot circuit | 470 psi |

Hydraulic cylinders | |

Number of cylinders | Bore x Stroke x Rod Diameter |

Boom / 2 | 5.1 x 52.5 x 3.5 in |

Arm / 1 | 5.3 x 58.7 x 3.7 in |

Bucket / 1 | 4.5 x 44.1 x 3.2 in |

Drives and Brakes | |

Steering control | Two levers with pedals |

Drive method | Hydrostatic |

Maximum drawbar pull | 45,349 lbs. |

Gradeability | 70%, 35° |

Maximum travel speed: (Auto-Shift) | |

High | 3.4 mph |

Mid | 2.5 mph |

Low | 1.9 mph |

Service brake | Hydraulic lock |

Parking brake | Mechanical disc brake |

Swing System | |

Drive method | Hydrostatic |

Swing reduction | Planetary gear |

Swing circle lubrication | Grease-bathed |

Service brake | Hydraulic lock |

Holding brake/Swing lock | Mechanical disc brake |

Swing speed | 12.4 rpm |

Swing torque | 49,907 ft.-lbs. |

Undercarriage | |

Center frame | X-frame |

Track frame | Box-section |

Seal of track | Sealed track |

Track adjuster | Hydraulic |

Number of shoes | 49 each side |

Number of carrier rollers | 2 each side |

Number of track rollers | 9 each side |

Sound Performance | |

Exterior – ISO 6395 | 100 dB(A) |

Operator – ISO 6396 | 66 dB(A) |

Coolant & Lubricant Capacity (Refilling) | |

Fuel tank | 105.7 US gal |

Coolant | 8.1 US gal |

Engine | 6.1 US gal |

Final drive, each side | 1.3 US gal |

Swing drive | 1.7 US gal |

Hydraulic tank | 34.9 US gal |

Hydraulic system | 61.8 US gal |

DEF tank | 6.1 US gal |

Operating Weight (Approximate) | |

Operating Weight (Approximate) | |

Operating weight includes 18 ft. 8 in one-piece boom, 9 ft. 7 in arm, SAE heaped 1.57 yd3 bucket, rated capacity of lubricants, coolant, full fuel tank, operator, and standard equipment. | |

Triple-Grouser Shoes | |

28 in | |

31.5 in | |

Operating Weight | |

53,265 lbs. | |

53,882 lbs. | |

Ground Pressure | |

6.7 psi | |

5.9 psi |

Frequently Asked Questions

What are the specifications of the Komatsu PC210 excavator?

The Komatsu PC210 excavator, also known as the PC210 Komatsu, is a versatile and powerful machine designed for various excavation and construction applications. Key specifications of the PC210 include an operating weight ranging from 53,265 LBS to 53,882 LBS, a maximum digging depth of 22 Feet, and a maximum digging reach of 33 Feet. The PC210 has a 165-horsepower engine and features advanced hydraulic systems for smooth and precise operation.

Can you recommend compatible attachments for the Komatsu PC210 excavator?

Various attachments are compatible with the Komatsu PC210 excavator to enhance its versatility and productivity. Standard attachments include buckets, hydraulic breakers, thumbs, grapples, compactors, and rippers. These attachments are designed to perform specific tasks such as excavation, material handling, demolition, and compaction. Our team can provide personalized recommendations based on your project requirements and the capabilities of your PC210 excavator.

How do I ensure proper compatibility between my PC210 Komatsu excavator and attachments?

Ensuring compatibility between your PC210 Komatsu excavator and attachments is crucial for optimal performance and safety. Before purchasing or renting an attachment, consider factors such as hydraulic flow and pressure requirements, weight capacities, and mounting configurations. Our experts can assist you in selecting compatible attachments and provide any necessary adaptors or fittings to ensure seamless integration with your PC210 excavator.

What maintenance is required for the Komatsu PC210 excavator?

Regular maintenance is essential for keeping the Komatsu PC210 excavator in optimal condition for efficient operation. Follow the manufacturer’s recommended maintenance schedule for tasks such as checking fluid levels, inspecting hydraulic hoses and fittings, greasing pivot points, and replacing filters and fluids as needed. Additionally, inspect the machine for signs of wear or damage before each use and address any issues promptly to prevent further damage or safety hazards.

Can I use third-party attachments with my Komatsu PC210 excavator?

While Komatsu offers a range of high-quality attachments designed explicitly for the PC210 excavator, third-party attachments may also be compatible. However, it’s important to ensure that third-party attachments meet safety standards and specifications outlined by Komatsu for use with the PC210. Our team can provide guidance on selecting reputable third-party attachments and verifying compatibility with your excavator to ensure safe and efficient operation.

How do I find more information about the specifications and capabilities of the Komatsu PC210 excavator?

For detailed information about the requirements and capabilities of the Komatsu PC210 excavator, refer to the manufacturer’s website or product brochure. You can also consult with our team of experts, who can provide additional insights and recommendations based on their extensive knowledge and experience with Komatsu excavators and attachments.