Grapples

Hawk Excavator Grapples are versatile attachments designed to enhance the functionality and efficiency of excavators across various industries and applications. At Hawk Excavator, we offer a comprehensive range of grapples tailored to meet the diverse needs of our customers. Our lineup includes four main types of grapples: mechanical, hydraulic, demolition, and rotary hydraulic, each engineered for specific tasks and operating conditions.

At Hawk Excavator, our grapples are engineered to deliver superior performance, durability, and reliability in the most demanding work environments. With precision engineering, high-quality materials, and innovative design, our grapples provide operators with the tools they need to tackle tough jobs efficiently and effectively.

Choose Hawk Excavator grapples for unmatched strength, versatility, and productivity on the job site.

Excavator Tonnage: 1-40 Ton

Type: Top, Side, Box (Noise Reducer)

Chisel Options: Moil point, Blunt, Flat chisel, Conical point

Applications: Break up concrete, rock, and other hard materials

Demolition Grapples

Designed for heavy-duty demolition and site cleanup operations, Hawk Excavator demolition grapples feature reinforced jaws and robust construction to withstand the rigors of harsh environments. These grapples excel at gripping and manipulating heavy debris, concrete rubble, and structural components during demolition projects. With their high gripping force and rugged build, demolition grapples ensure efficient material handling and enhanced productivity on the job site.

Hydraulic Grapples

Hawk Excavator’s hydraulic grapples provide the versatility and precision required for a wide range of material handling tasks. Powered by the excavator’s hydraulic system, these grapples offer adjustable gripping force and precise control, allowing operators to handle delicate or irregularly shaped objects with ease. Whether it’s loading, sorting, or lifting materials, hydraulic grapples excel in applications such as waste management, recycling, forestry, and landscaping.

Mechanical Grapples

Hawk Excavator’s mechanical grapples are rugged and reliable attachments ideal for handling bulky materials such as logs, rocks, debris, and waste. Featuring heavy-duty construction and high-tensile steel components, these grapples ensure durability and longevity even in demanding environments. With their simple yet robust design, mechanical grapples offer efficient material handling capabilities for forestry, construction, demolition, and land clearing applications.

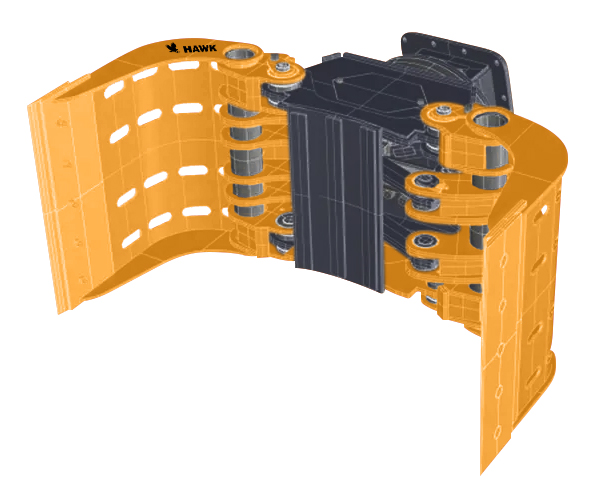

Rotating Hydraulic Grapples

HAWK Excavator rotary hydraulic grapples combine the functionality of a standard hydraulic grapple with the added capability of 360-degree rotation. This rotational feature allows operators to easily position and manipulate loads without repositioning the excavator, increasing productivity and efficiency. Whether it’s loading/unloading, sorting, or placing materials, rotary hydraulic grapples offer unmatched versatility and maneuverability for a wide range of applications, including material handling, forestry, and scrap handling.

Benefits of Grapples

Enhanced Efficiency: Hawk Excavator grapples streamline material handling tasks, allowing operators to lift, sort, and move materials with precision and speed. By minimizing manual labor and maximizing machine efficiency, our grapples help expedite project timelines and increase overall productivity on the job site.

Versatile Functionality: With a wide range of grapple types available, including mechanical, hydraulic, demolition, and rotary hydraulic options, our lineup offers versatility to tackle diverse applications. Whether it’s loading, sorting, lifting, or demolishing, our grapples provide the versatility needed to adapt to changing job site requirements.

Improved Safety: Safety is paramount in heavy equipment operations, and Hawk Excavator grapples are designed with safety features to protect both operators and equipment. Features such as hydraulic pressure relief valves and reinforced structures ensure safe and secure operation, reducing the risk of accidents and injuries on the job site.

Increased Precision: Hydraulic grapples equipped with adjustable gripping force allow operators to exert precise control over materials, minimizing damage and waste. This precision handling capability is particularly beneficial when working with delicate or irregularly shaped objects, ensuring efficient and accurate material placement.

Enhanced Durability: Built with heavy-duty materials and reinforced welds, Hawk Excavator grapples are engineered to withstand the toughest working conditions. Wear-resistant components such as replaceable teeth and cutting edges extend the lifespan of the grapple, reducing maintenance costs and downtime.

Optimized Performance: Our grapples are designed for seamless integration with excavators, ensuring optimal performance and compatibility. Easy installation and quick attachment changes minimize downtime, allowing operators to maximize uptime and keep projects on schedule.

Cost Savings: By streamlining material handling processes and reducing manual labor, Hawk Excavator grapples help lower operational costs and increase overall profitability. Additionally, their durable construction and long lifespan result in lower maintenance expenses over time, providing a solid return on investment for contractors and operators.

Hawk Excavator Grapple Features

At Hawk Excavator, our grapples are engineered with precision and durability to meet the rigorous demands of the construction, forestry, demolition, and waste management industries. Here are some key features of our excavator grapples:

Heavy-Duty Construction: Our grapples are constructed with high-strength materials such as hardened steel to withstand the toughest working conditions. Reinforced welds and structural components ensure long-lasting durability and reliability.

Versatile Design: With various types of grapples available, including mechanical, hydraulic, demolition, and rotary hydraulic, our lineup offers versatility to handle diverse material handling tasks. Whether it’s loading, sorting, lifting, or demolition, our grapples are designed to excel in a wide range of applications.

Adjustable Gripping Force: Hydraulic grapples feature adjustable gripping force, allowing operators to control the pressure exerted on materials for precise handling. This feature enhances operational flexibility and efficiency, especially when dealing with delicate or irregularly shaped objects.

360-Degree Rotation (Rotary Hydraulic Grapples): Rotary hydraulic grapples are equipped with a rotating mechanism that provides full 360-degree rotation. This allows operators to position and manipulate loads with ease, eliminating the need for constant repositioning of the excavator.

Easy Installation and Compatibility: Our grapples are designed for quick and easy installation, ensuring minimal downtime and maximum productivity on the job site. They are compatible with a wide range of excavator makes and models, providing versatility and convenience for operators.

Enhanced Productivity: With superior gripping force, precise control, and versatile functionality, our grapples help increase productivity and efficiency on the job site. Whether handling bulk materials, debris, or demolition waste, our grapples enable operators to complete tasks quickly and effectively.

Durable Wear Components: Wear-resistant components such as replaceable teeth and cutting edges are integrated into our grapple designs to withstand the abrasive effects of continuous use in tough environments. This ensures long-term reliability and performance.

Safety Features: Safety is paramount in heavy equipment operations. Our grapples are equipped with safety features such as hydraulic pressure relief valves and reinforced structures to prevent accidents and ensure operator protection during operation.

Grapples Frequently Asked Questions

What excavator sizes are compatible with your grapples?

Our grapples are compatible with a wide range of excavator sizes, ranging from compact mini excavators to large excavators. We offer grapples designed to fit excavators of various sizes, ensuring compatibility with your specific equipment.

What materials are your grapples suitable for handling?

Our grapples are designed to handle a variety of materials, including rocks, logs, construction debris, scrap metal, and more. Whether you’re working in construction, forestry, demolition, or waste management, our grapples provide efficient material handling solutions.

Can your grapples be operated remotely?

Some of our hydraulic and rotary hydraulic grapples can be operated remotely, providing added convenience and safety on the job site. Remote operation allows operators to control the grapple from a safe distance, minimizing exposure to hazards.

Do your grapples come with warranty coverage?

Yes, our grapples come with warranty coverage to ensure peace of mind for our customers. Warranty terms may vary depending on the type of grapple and other factors, so be sure to inquire about warranty details when purchasing.

Are your grapples easy to install and use?

Yes, our grapples are designed for easy installation and user-friendly operation. They come with clear instructions and are compatible with standard excavator attachments, allowing for quick and hassle-free setup.

What maintenance is required for your grapples?

Our grapples are built to withstand the rigors of heavy-duty use, but regular maintenance is still recommended to ensure optimal performance and longevity. Maintenance tasks may include lubrication, inspection of wear parts, and occasional replacement of components.

Can your grapples be customized to suit specific requirements?

Yes, we offer customization options for our grapples to meet specific customer needs. Whether you require a custom size, additional features, or specialized attachments, our team can work with you to create a tailored solution.

Grapples Carried By Hawk Excavator

Mechanical Grapple

CAT 320 Hydraulic Grapple

CAT 349 Hydraulic Grapple

CAT 336 Hydraulic Grapple

CAT 325 Hydraulic Grapple

Komatsu PC210 Hydraulic Grapple

Komatsu PC490 Hydraulic Grapple

Komatsu PC400 Hydraulic Grapple

Komatsu PC360 Hydraulic Grapple

Hitachi EX120 Hydraulic Grapple

John Deere 200G Hydraulic Grapple

John Deere 470G Hydraulic Grapple

John Deere 350G Hydraulic Grapple

John Deere 245G Hydraulic Grapple

John Deere 210G Hydraulic Grapple

Volvo EC480 Hydraulic Grapple

Case CX210 Hydraulic Grapple

CAT 320 Rotary Hydraulic Grapple

CAT 325 Rotary Hydraulic Grapple

CAT 336 Rotary Hydraulic Grapple

Komatsu PC210 Rotary Hydraulic Grapple

Komatsu PC360 Rotary Hydraulic Grapple

Komatsu PC400 Rotary Hydraulic Grapple

Hitachi EX120 Rotary Hydraulic Grapple

John Deere 200G Rotary Hydraulic Grapple

John Deere 245G Rotary Hydraulic Grapple

John Deere 210G Rotary Hydraulic Grapple

John Deere 350G Rotary Hydraulic Grapple

Case CX210 Rotary Hydraulic Grapple