In the intricate world of construction and demolition, the long reach excavator is a pivotal innovation, dramatically transforming worksite operational efficiency. These machines, distinguished by their extended arm and boom, enable professionals to tackle projects that demand extra reach and precision, such as deep excavation, dredging, and slope shaping. Among the leading advancements in this field are the long-reach arms offered by HAWK Excavator, designed to extend traditional excavators’ capabilities far beyond their standard reach.

HAWK Excavator’s long reach arms are engineered to enhance reach and improve the machine’s stability and lifting capacity. This allows for more efficient completion of otherwise challenging and time-consuming tasks. Whether reaching across rivers to perform dredging work or safely demolishing structures from a distance, these arms facilitate operations in ways that conventional equipment cannot match. This comprehensive guide explores how maximizing the use of HAWK Excavator’s long-reach arms can lead to significant advancements in project efficiency, safety, and overall cost management, revolutionizing the approach to modern excavation and construction tasks.

Understanding Long Reach Excavators:

A long-reach excavator is a type of heavy construction equipment characterized by its extended arm and boom, providing it with significantly greater reach and depth capabilities than standard excavators. This specialized machine is designed to perform tasks in inaccessible or unsafe areas for conventional excavators, making it an essential tool in construction, demolition, and dredging projects.

Unique Features of a Long Reach Excavator

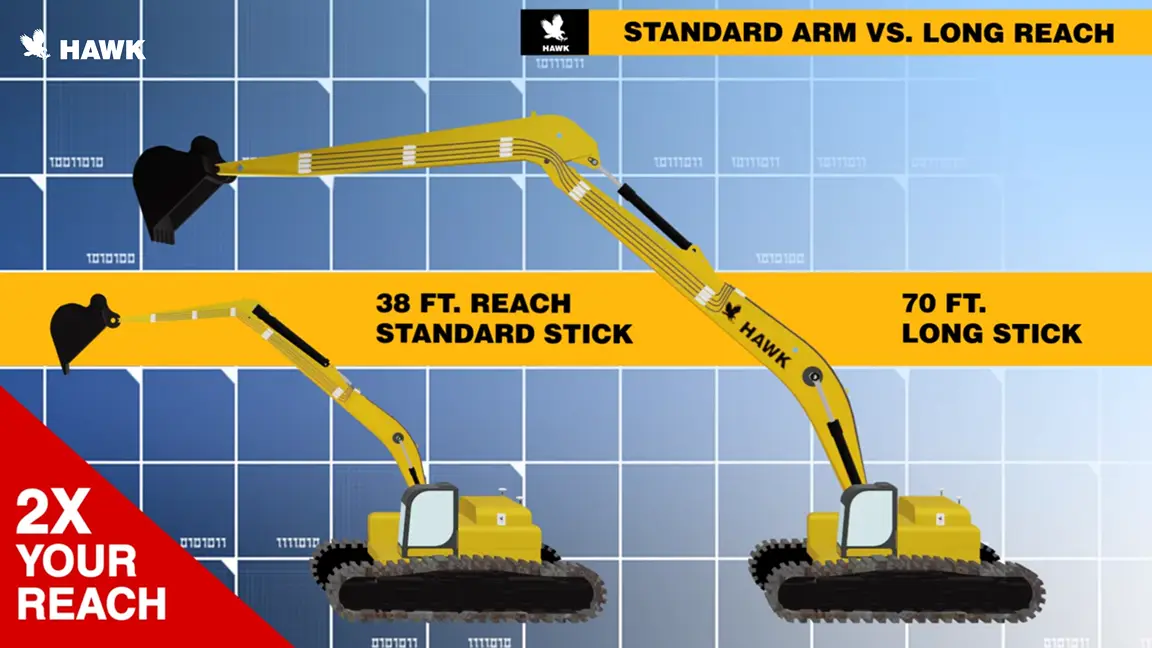

The most distinct feature of a long reach excavator is its elongated arm. The arm and boom of a long reach excavator can extend to 40 to 100 feet long, much longer than the approximately 10 to 15 feet of a standard excavator’s arm. This extended reach allows operators to maintain a safe distance from the work site, such as in situations involving water or unstable terrain. Other significant features include:

- Lightweight Construction: Despite their size, the booms and arms of long reach excavators are designed to be relatively lightweight. This design minimizes the load on the machine’s chassis, maintaining stability and ease of handling even when the arm is fully extended.

- Enhanced Hydraulics: Long reach excavators have advanced hydraulic systems to manage the increased pressure and load associated with operating such a long arm. These systems ensure smooth, precise movements and provide sufficient power to the attachment, whether a bucket, clamp, or other tool.

- Stabilizing Features: Due to the extended reach, these machines often include additional stabilizing features such as wider tracks and counterweights. These adaptations help prevent the excavator from tipping over when the arm is extended and loaded, mainly when working at the edges of embankments or over water.

Applications of a Long Reach Excavator

- Dredging: These excavators are ideal for dredging operations in rivers, lakes, and ponds. They can safely remove silt, debris, and other materials from a body of water while positioned on the shore, eliminating the need for floating dredges in some cases.

- Deep Excavation: Long reach excavators can dig deep trenches and holes without the need for the machine to be positioned close to the edge of the excavation site. This capability is crucial in situations where the surrounding ground may be unstable or prone to collapse.

- Demolition: In urban and suburban environments, long reach excavators are used to demolish structures from a safe distance. They can tear down walls, roofs, and other structural elements while keeping operators and workers safe from hazards like falling debris.

- Environmental Cleanup: These excavators are also used in environmental cleanup projects, such as removing contaminated soil. Their extended reach allows them to work in sensitive environments without causing additional disturbance to the surrounding area.

- Construction on Waterfronts: Long reach excavators can assist in constructing and maintaining waterfronts and embankments. They can place rocks and other materials to prevent erosion or construct barriers without entering the water.

Key Industries Benefiting from Long Reach Excavators:

Long reach excavators are specialized equipment that significantly enhance operational capabilities in various key industries. These industries benefit from the unique features of long reach excavators, such as their extended reach, improved precision, and ability to operate in challenging environments. Here are some of the key industries that benefit from the use of long reach excavators and how they gain advantages:

Construction Industry

Benefit: In the construction industry, long reach excavators are crucial for handling large-scale projects that require extended reach, such as building bridges, constructing retaining walls, or working on large buildings. These excavators can operate from a safe distance while handling tasks that would otherwise require complex setups or multiple pieces of equipment.

Application: For example, during the construction of a bridge, long reach excavators can be used to place heavy materials or perform earthmoving tasks from one side of the riverbank without needing to set up additional infrastructure in the middle of the river.

Demolition

Benefit: Demolition projects benefit from long reach excavators‘ capacity to tear down structures from a safe distance, minimizing the risk to operators and surrounding areas. These machines can reach high elevations or extend across unstable ground to dismantle buildings, making the process safer and more efficient.

Application: Long reach excavators are often seen in urban environments, where they safely demolish parts of buildings close to busy streets or other structures, ensuring minimal disruption and maintaining safety standards.

Dredging and Water Management

Benefit: Long reach excavators are essential in dredging operations for removing silt, debris, and other materials from bodies of water. Their long arms allow them to work from the shoreline or riverbanks, eliminating the need for more invasive dredging methods.

Application: They are used to maintain waterways, ensuring they are free of obstructions that could impact commercial shipping or lead to flooding. Additionally, they are used in constructing and maintaining levees and stormwater management systems.

Environmental Remediation

Benefit: These excavators play a significant role in environmental remediation by enabling safe and efficient removal of contaminated materials from sensitive sites. Their ability to operate remotely helps prevent the spread of contaminants and reduces the ecological impact of cleanup operations.

Application: Long reach excavators can remove contaminated soil from a distance or manage waste materials in landfill operations, minimizing the interaction between operators and hazardous substances.

Mining and Quarrying

Benefit: In mining and quarrying, long reach excavators extract materials from deep pits or reach difficult positions where standard equipment cannot operate. Their extended reach maximizes efficiency by reducing the need to move the excavator frequently.

Application: These machines are particularly useful in quarries for reaching down to extract rock and are used in strip mining operations to handle overburden removal with greater ease.

Landscaping and Agricultural Operations

Benefit: Long reach excavators can be used in landscaping and agriculture to construct irrigation systems and large-scale landscaping projects. They can work over obstacles or across vast areas, such as streams or roads, without disturbing the existing structures or vegetation.

Application: For instance, they are used to dig or maintain drainage ditches and irrigation canals across large agricultural fields, enhancing water management without causing extensive disruption to the land.

In-depth Review: Caterpillar Long Reach Excavators:

Caterpillar, a renowned construction equipment industry player, offers a range of long-reach excavators designed to meet the demanding requirements of various sectors, including construction, mining, and water management. Caterpillar long reach excavators are known for their robustness, efficiency, and advanced technological features, making them a top choice for businesses looking to enhance their operational capabilities. This in-depth review will cover the critical aspects of Caterpillar long reach excavators, focusing on their specifications, performance, and applications.

Performance and Specifications

Caterpillar long reach excavators are built to deliver exceptional performance in challenging environments. These machines feature powerful engines and advanced hydraulic systems that ensure efficient operation and precise handling. The long reach models typically offer reaches extending over 50 feet, with larger models providing even greater reach capabilities. This allows for significant flexibility in various applications, from deep trench digging to river dredging.

The design of these excavators includes reinforced booms and arms, which are engineered to withstand the stresses of extended-reach operations without compromising the machine’s stability or performance. Caterpillar’s long reach excavators also come equipped with state-of-the-art safety features, including anti-tip technology and enhanced visibility options, which are crucial when operating in complex or densely populated sites.

Durability and Maintenance

Caterpillar long reach excavators are designed with durability in mind. High-quality materials and robust construction techniques ensure that these machines can endure the rigors of heavy-duty use. Thanks to Caterpillar’s design, maintenance is also simplified. It provides easy access to common maintenance points, reducing downtime and helping to keep long-term operating costs low.

Technology and Features

One of the standout features of Caterpillar long reach excavators is their integrated technology. These machines often come equipped with Cat Connect Technology, which offers a range of features like real-time tracking, health monitoring systems, and productivity analysis tools. These technologies not only enhance the operational efficiency of the excavators but also provide valuable data that can be used to optimize performance and reduce costs.

Additionally, Caterpillar’s operator cabins are designed with comfort and functionality in mind, featuring ergonomic controls, advanced noise reduction, and climate control systems. This ensures that operators can work comfortably for extended periods, which maximizes productivity.

Applications

Caterpillar long reach excavators are versatile machines that can be used across various industries. They are ideal for projects requiring extended reach, such as constructing retaining walls or performing complex grading tasks. In the water management sector, these excavators are perfect for dredging operations and maintaining waterways, where their extended reach allows for work to be conducted from stable ground without disturbing the aquatic ecosystem.

Renting Options

For businesses still waiting to invest in a permanent addition to their fleet, finding a Caterpillar long reach excavator for rent provides a flexible and cost-effective solution. Renting allows companies to adapt to project-specific needs with the right equipment without the total purchase commitment. This is particularly beneficial for short-term projects or companies operating under tight budgets. Rental providers often offer a range of models, ensuring that clients can choose the best configuration for their specific project requirements.

Caterpillar long reach excavators are robust, technologically advanced, and versatile, making them a valuable asset for any company needing extended reach capabilities. Whether purchased or acquired as a long reach excavator for rent, these machines can significantly boost productivity and efficiency on a wide range of project sites. With Caterpillar’s reputation for quality and support, clients can expect reliable performance and excellent service, making these excavators a wise choice for businesses looking to tackle challenging projects with confidence.

Renting vs. Buying: A Strategic Decision:

When considering whether to rent or buy a long reach excavator from HAWK Excavator, it’s essential to evaluate various factors to make the most cost-effective and practical decision for your project needs. Let’s delve into the details:

Pros of Renting a Long Reach Excavator for Rent:

Cost-Effectiveness: Renting a long reach excavator for rent can be more cost-effective upfront than buying one, as it avoids the significant initial investment required for ownership.

Flexibility: Renting allows you to use the excavator for specific projects or durations without committing to long-term ownership. This is particularly beneficial if you have intermittent or short-term needs.

No Maintenance Costs: Rental agreements often include maintenance and repair services, saving you from bearing additional costs and ensuring that the equipment is in optimal condition.

Access to Latest Models: Rental companies frequently update their fleets, providing access to newer models with advanced features without the hassle of ownership.

Cons of Renting a Long Reach Excavator for Rent:

Long-term Costs: While renting may seem cost-effective initially, over a prolonged period, the cumulative rental expenses can exceed the purchase price of the equipment.

Limited Availability: During peak seasons or in areas with high demand, the specific model of long reach excavator you require may not be readily available for rent when needed.

No Equity: Renting does not build equity in the equipment, and you won’t have the asset readily available for future projects or resale.

Pros of Buying a Long Reach Excavator:

Ownership: Buying a long reach excavator grants you complete ownership and control over the equipment, allowing you to use it whenever necessary without rental restrictions.

Long-term Cost Savings: Despite the significant initial investment, purchasing an excavator can be more cost-effective in the long run, mainly if you use it continuously or frequently.

Equity Building: As you pay off the equipment, you build equity, and if needed, you can sell it later, recouping some of your investment.

Customization: Ownership allows for customization of the long reach excavator to suit your specific project needs, enhancing efficiency and productivity.

Cons of Buying a Long Reach Excavator:

High Initial Investment: Buying a long reach excavator requires a substantial upfront investment, which may only be feasible for some businesses or projects.

Maintenance Costs: You’re responsible for all maintenance and repair costs, which can be unpredictable and potentially expensive over time.

Depreciation: Like any equipment, the excavator will depreciate over time, reducing its resale value.

How to Choose the Right Long Reach Excavator for Your Project:

Choosing the right long reach excavator for your project is crucial for ensuring efficiency, safety, and cost-effectiveness. Here are the key steps and considerations to help you select the most suitable long reach excavator for your specific needs:

- Size and Scope: Determine the size of the project and the scope of work. Larger projects may require excavators with higher power and more extended reach.

- Environment: Consider the project environment. If you are working in a sensitive ecological area, you might need an excavator with specific environmental compliance features.

- Digging Depth and Reach: Assess the maximum depth and reach required for the project. Long reach excavators come in various sizes and reach capacities, so matching these specifications with your project needs is essential.

- Material Handling: Evaluate the type of material the excavator will need to handle. Some excavators are better suited for digging, while others might be optimized for dredging or material placement.

- Arm Length: The length determines how far and deep the excavator can reach. Make sure the arm length meets or exceeds the requirements for your project.

- Operating Weight and Power: The excavator’s weight and power affect its stability and capability. Heavier and more powerful machines can handle more challenging tasks but may require more space and sturdier ground conditions.

- Bucket Capacity: Choose a bucket size that is efficient for your work. While more giant buckets can move more material, they may reduce precision and increase fuel consumption.

- Mobility and Transport: Consider how easily the excavator can be transported around the project site. Some models are more accessible to transport and more versatile in different terrains.

- Hydraulic Systems: Advanced hydraulic systems can improve the precision and efficiency of the excavator. Look for systems that offer fine control for delicate operations.

- Technology and Automation: Modern excavators may include technology like GPS, automated systems, and real-time data monitoring, which can enhance operation accuracy and efficiency.

- Safety Features: Ensure the excavator has adequate safety features, including visibility enhancements, stable platforms, and emergency stop mechanisms.

Maintenance Tips for Long Reach Excavators:

Maintaining a long reach excavator is crucial for ensuring its longevity, efficiency, and safety. Regular and proper maintenance can significantly reduce the risk of costly repairs and downtime, especially when dealing with such specialized equipment. Here are some essential maintenance tips for owners and operators of long reach excavators, including those with a long reach excavator for rent. These guidelines will help keep the machinery in top condition, ensuring optimal performance on any project.

Daily Checks and Routine Maintenance

- Fluid Levels: Check the hydraulic oil, engine oil, coolant, and fuel levels daily. Proper fluid levels are crucial for the efficient operation of long reach excavators. Low levels can lead to mechanical failures and increased wear.

- Filters: Regularly inspect and clean or replace air, fuel, and hydraulic filters. Clean filters ensure that systems are free from contaminants, which can extend the life of the engine and hydraulic components.

- Lubrication: Regularly grease the machine’s moving parts, such as pins and bushings, to reduce friction and wear. The boom, arm, and bucket joints of a long reach excavator require frequent lubrication due to their extended range of motion and heavy-duty tasks.

Inspect Hydraulic System

- Hoses and Belts: Check hydraulic hoses and belts for signs of wear, cracks, or leaks. The hydraulic system is critical in long reach excavators, as it powers the movement and operation of the arm and bucket. Promptly replace any damaged components to prevent failures.

- Hydraulic Fluid: Monitor the condition of the hydraulic fluid. Dark, dirty, or gritty fluid can indicate contamination, damaging the hydraulic system. Change the fluid and clean the hydraulic system according to the manufacturer’s recommendations.

Check the Undercarriage

- Track Tension: Regularly inspect and adjust the track tension according to the manufacturer’s guidelines. Incorrect tension can lead to increased wear and potential track slippage or breakage.

- Wear and Damage: Inspect the undercarriage for excessive wear or damage, including rollers, idlers, and sprockets. The undercarriage bears the weight and movement of the long reach excavator, making it susceptible to significant wear.

Monitor Electrical Systems

- Batteries and Wiring: Check the condition of the batteries and ensure that all wiring connections are secure and corrosion-free. Electrical systems are crucial in starting the engine and operating the excavator’s electronic components.

- Lights and Indicators:Ensure that all lights and indicators function correctly to maintain safety, primarily if the long-reach excavator operates in the early morning or night hours.

Structural Integrity

- Boom and Arm: Inspect the boom and arm of the long reach excavator for any signs of stress, cracks, or bends. Due to their extended reach, these components can undergo significant stress, especially during heavy lifting or digging tasks.

- Welds and Joints: Examine all welds and joints on the excavator for integrity. Repair any cracks or weak spots immediately to prevent structural failures.

Cleaning and Storage

- Regular Cleaning: Clean the excavator regularly to prevent the buildup of dirt and debris, which can hide potential issues or damage and lead to rust and corrosion.

- Proper Storage: When not in use, store the long reach excavator in a covered and dry area to protect it from the elements. Proper storage can prevent weather-related damage and extend the life of the machine.

Record Keeping

- Maintenance Logs: Maintain detailed records of all maintenance and repairs. Logs can help track the excavator’s health over time, facilitate timely maintenance, and be essential for warranty claims and resale value.

Long Reach Excavator Future Trends:

The excavator industry is undergoing significant transformations driven by technological advancements, changing environmental regulations, and evolving market demands. As companies and operators seek more efficient, sustainable, and cost-effective solutions, several future trends are emerging in excavator technology. Here are some of the key trends that are likely to shape the future of this vital industry:

Electrification

As environmental concerns become more pressing, the shift towards electric and hybrid excavators is accelerating. These machines produce fewer emissions and are quieter than their diesel counterparts, making them ideal for urban and environmentally sensitive projects. Manufacturers are investing in developing battery technologies and electric drive systems that can provide the power and endurance needed to compete with traditional models, aiming to reduce the carbon footprint of construction activities.

Automation and Robotics

Automation is set to revolutionize the excavator industry by enhancing safety, efficiency, and precision. Autonomous or semi-autonomous excavators can operate in hazardous environments without putting operators at risk. Robotics technology, including robotic arms controlled remotely or through programmed tasks, is also integrated to perform repetitive or precision-demanding tasks. These developments improve operational safety and compensate for skilled labor shortages in the industry.

Connectivity and IoT Integration

Integrating the Internet of Things (IoT) in excavators allows for better data collection and analysis, leading to optimized machine performance and maintenance. Excavators with IoT sensors can monitor parameters such as fuel consumption, operational hours, and engine health in real time. This connectivity enables predictive maintenance, identifying and addressing potential issues before they lead to equipment failure, minimizing downtime and repair costs.

Advanced Guidance and Control Systems

Future excavators will increasingly incorporate advanced guidance systems, including GPS and 3D imaging technologies, to aid operators. These systems provide precise digging and navigation capabilities, reducing errors and enhancing efficiency. Operators can pre-program dig sites using 3D models, allowing the excavator to adjust its path and digging depth to match exact specifications, thus improving accuracy and reducing waste.

Enhanced Operator Comfort and Safety

As the focus on operator safety and comfort increases, manufacturers are designing cabins with better ergonomics, improved visibility, and advanced safety features. Noise reduction, vibration control, and climate control systems are becoming standard. Furthermore, safety features such as object detection sensors, camera systems for 360-degree visibility, and emergency stop mechanisms are being integrated to protect operators and site personnel.

Sustainable Practices and Materials

The excavator industry is also moving towards using sustainable materials and manufacturing processes. This includes the development of biodegradable hydraulic fluids and the use of recycled materials in construction. Such practices help reduce the environmental impact of manufacturing excavators and appeal to companies aiming to meet sustainability goals.

Modular and Multifunctional Designs

The future of excavators lies in versatility. Modular designs allowing easy attachment changes and multifunctional capabilities will enable a single excavator to perform various tasks. From traditional digging to drilling, piling, and cutting these adaptable machines can switch roles quickly, reducing the need for multiple specialized machines on a single job site.

Conclusion

Long reach excavators represent a pivotal innovation in construction, demolition, and dredging, offering extended reach and enhanced capabilities. By understanding their unique features, applications, and future trends, businesses can harness their power to revolutionize project efficiency, safety, and sustainability. Whether through renting or buying, optimizing maintenance, or embracing emerging technologies, long reach excavators promise to shape the future of the industry, driving progress toward more efficient, sustainable, and cost-effective construction practice