Guide To Excavator Attachments

Learn about the various attachments that can enhance an excavator in multiple industrial applications.

This Article Includes

- Excavators are the Most Versatile Type of Heavy-Equipment

- Different Types of Excavator Attachments and Their Use?

- Powering Your Excavator Attachments

Excavators are the Most Versatile Type of Heavy-Equipment

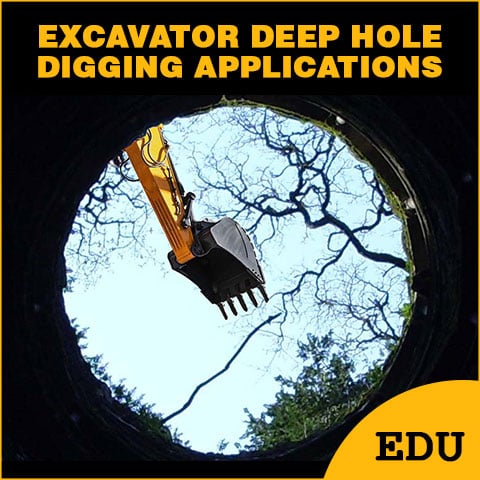

Excavators come in many different brands, variations, shapes, sizes, and weights, and they are responsible for performing most of the tasks that heavy construction equipment accomplishes at a job site. One of the first steps to capitalizing on excavators’ incredible versatility is to know the different types of attachments and what they can be used for. Besides being used in many industries, excavators serve many specific purposes that range from digging, grading, dredging, drilling, material handling, removing vegetation, and more.

Versatility and Applications of Excavators:

Excavators are among the most versatile pieces of heavy machinery, able to switch between numerous tasks with the right attachments. The great options available when it comes to excavators in terms of brands, weight and power means there is always an excavator that is perfect for your industry. This versatility makes them indispensable in construction, mining, landscaping, and many other industries. To dig trenches, grade surfaces, drench waterways, drill holes, handle materials, or clear vegetation, excavators can be equipped with specialized excavator attachments to handle each job efficiently and effectively.

Importance of Choosing the Right Attachment:

Numerous excavator attachments are designed for specific tasks with the many available excavators for sale. Without understanding what attachment is best for your particular needs, a lot of time and money can be wasted on a job of lower quality than required. Choosing the right attachment is crucial to optimizing excavators‘ performance and productivity. The right information can make the options for your industry’s best excavator so much clearer. For instance, using a grading bucket for fine leveling or a rock bucket for heavy-duty excavation ensures that the machine operates at its peak efficiency, no matter the excavator weight.

What are the Different Types of Excavator Attachments (AKA Worktools)?

Excavator attachments, also known as worktools, significantly enhance excavators’ quality, versatility, and functionality. Buckets are the most common and essential excavator attachments designed for specific tasks and operational needs. Let’s delve into the different types of excavator bucket attachments, from the most commonly used to more specialized ones you can find for sale.

Buckets

Buckets are the quintessential excavator attachment, used in various quality applications from digging and grading to handling materials. Depending on the task, there are wide buckets, slim buckets, buckets with teeth for digging, and smooth buckets for materials handling. Below are the different types of buckets commonly used as an excavator attachment.

Digging Bucket: #1 Most Popular Attachment

Originally, all digging and grading buckets were affixed with teeth. The teeth on a digging bucket penetrate and break up hard, compact soil, making these buckets highly effective for excavation work. They come in various widths and are also well-suited for rocky environments.

Common Uses:

1. Digging Foundations: Digging bucket attachments for excavators are essential for creating foundations for buildings and other structures. The teeth on the digging bucket allows it to break through hard soil and rocks, ensuring a stable and level base for construction. This makes the digging bucket an indispensable excavator attachment in construction projects requiring precise and deep excavation.

2. Excavating Trenches: These excavator buckets are perfect for trenching operations, such as laying pipelines, cables, and drainage systems. The teeth help to cut through tough soil and roots, creating clean and accurate trenches. This is particularly important in utility installations where the trench dimensions must be precise to ensure proper placement and function of the pipes or cables.

3. Removing Stumps and Roots: Digging buckets in excavators is also highly effective in land clearing operations. The strong teeth can grasp and pull out tree stumps and roots from the ground. This capability is crucial for preparing land for new construction, agricultural use, or landscaping, where removing old vegetation is necessary to create a clear and level site.

Features:

1. Teeth for Breaking Tough Materials: The primary feature of a digging bucket is its teeth, specifically designed to penetrate hard and compact soils. These teeth break up the material, allowing for easier and more efficient excavation. The teeth of the bucket are typically made from high-strength steel, ensuring durability and longevity even in harsh working conditions for excavators.

2. Available in Multiple Widths: Digging buckets come in various widths to accommodate different excavation needs. Broader buckets are used with excavators for large-scale excavation projects to move more material in less time. In comparison, narrower buckets are ideal for precise digging operations, such as trenching or working in confined spaces. The availability of multiple widths allows operators to choose the right bucket as excavator attachments, enhancing the excavator’s efficiency and effectiveness.

3. Requires Auxiliary Hydraulic Power for Optimal Performance: Digging buckets often require auxiliary hydraulic power to maximize their effectiveness. This additional power helps to operate the bucket’s teeth and improve the digging force. The auxiliary hydraulics ensure the bucket can handle rigid materials and provide the necessary force for deep excavation tasks. This feature is crucial for maintaining high productivity and efficiency in demanding excavation projects.

Rock Bucket: #2 Most Popular Attachment

Rock buckets are the heavy-duty version of the digging bucket. These excavator attachment buckets are designed for the most challenging jobs, with hardened teeth and a reinforced structure to withstand abrasive and rugged applications.

Common Uses:

1. Excavating in Rocky Terrain: Rock buckets excel in environments where the soil is filled with rocks and other hard materials. Their reinforced structure and hardened teeth allow them to penetrate and break through rocky ground. This capability is essential for construction projects in mountainous or rocky areas where standard digging buckets would struggle or wear out quickly.

2. Mining Industry: Rock buckets are indispensable for extracting minerals and ores in the mining industry. They are designed to handle the extreme conditions and abrasive materials commonly found in mining operations. These excavator attachments can dig into rock faces and scoop out large volumes of material, making them crucial for surface and underground mining activities.

3. Heavy Demolition Work: Rock buckets are also vital for heavy demolition work, such as tearing down reinforced concrete structures and breaking up large rocks and boulders. Their durability and strength allow them to withstand the impact and stress of demolition activities, making them ideal for projects involving the removal of old buildings, bridges, and other large structures.

Features:

1. Hardened Teeth for Enhanced Durability: One key feature of rock buckets is their hardened teeth. These teeth are designed to endure the high levels of wear and tear associated with digging in rocky and abrasive environments. The hardened material ensures that the teeth remain sharp and effective, even after extended use, providing a longer lifespan for the bucket.

2. Robust Design to Handle Abrasive Materials: Rock buckets are built with a reinforced structure to withstand harsh rock excavation and heavy demolition work conditions. The bucket body is typically made from high-strength steel and may include additional wear plates and reinforcements to protect against abrasion and impact. This robust design ensures the bucket can handle the toughest materials without excessive wear or damage.

3. Requires Auxiliary Hydraulic Power for Optimal Performance: Rock buckets often require auxiliary hydraulic power to achieve the best performance. This additional power enhances the bucket’s ability to break through tough materials and provides the necessary force for lifting and moving heavy rocks. The auxiliary hydraulics ensure the bucket operates effectively, even in the most challenging conditions.

Grading Bucket: #3 Most Popular Attachment

Grading buckets, or ditching or leveling buckets, have a flat, straight edge with no teeth. They are better suited for tasks that require a smooth finish, such as grading, leveling, and ditching.

Common Uses:

1. Smoothing and Leveling Surfaces: Grading buckets are ideal for creating smooth and even surfaces, which is crucial in various construction and landscaping projects. Whether preparing a site for paving, laying foundations, or creating a level area for recreational use, grading buckets ensure a high-quality finish. Their flat edge allows operators to achieve a consistent grade, making them indispensable for final surface preparation.

2. Ditch Cleaning: These buckets are perfect for cleaning and maintaining ditches, channels, and drainage systems. The wide, flat design enables efficient scooping and removal of debris, sediment, and vegetation from ditches, ensuring proper water flow and preventing blockages. This application is particularly important in agricultural, municipal, and infrastructure maintenance.

3. Landscaping Industry: In landscaping, grading buckets are used for various tasks, including creating garden beds, shaping terrain, and installing lawns. Their ability to level and smooth surfaces makes them essential for landscape design and construction. Whether building retaining walls, sculpting land contours, or preparing areas for planting, grading buckets provide the precision needed for aesthetically pleasing and functional landscapes.

Features:

1. Bucket has Flat Edge for Clean Finishes: The defining feature of grading buckets is their flat, straight edge, essential for achieving clean and precise finishes. This flat edge allows operators to scrape and level surfaces effectively, ensuring uniformity and smoothness. The absence of teeth also prevents gouging or tearing the ground, which is crucial for tasks that require a neat and even surface.

2. Wider than Digging Buckets for Efficient Coverage: Grading buckets are typically wider than digging buckets, providing greater surface coverage with each pass. This increased width allows for faster and more efficient grading and leveling, reducing the time and effort required to complete a project. The wider profile also helps distribute the load more evenly, preventing excessive pressure on the excavator and improving stability during operation.

3. Tilting Capability for Creating Angles: Many grading buckets are equipped with a tilting mechanism, allowing the operator to adjust the bucket’s angle. This tilting capability is essential for creating precise slopes, banks, and angled surfaces. It enables the excavator to perform complex grading tasks without needing to reposition frequently, enhancing efficiency and accuracy in operations such as ditching, terracing, and creating drainage gradients.

4. Requires Auxiliary Hydraulic Power for Optimal Performance: Grading buckets often require auxiliary hydraulic power to achieve optimal performance. The hydraulic system provides the force and control to operate the tilting mechanism and maintain consistent pressure during grading tasks. This ensures the bucket performs smoothly and effectively, even in demanding conditions. The auxiliary hydraulics enhance the bucket’s utility, making it suitable for various grading and leveling applications.

Other less common bucket excavator attachments include:

Trenching Bucket

Trenching buckets in excavator attachments have a thinner profile and are designed specifically for digging narrow trenches to install pipelines, cables, and drainage systems. Their precision reduces the disturbance to surrounding soil, minimizing restoration costs and time.

Common Uses:

Digging trenches for utility lines

Installing irrigation systems

Laying underground cables

Features:

Narrow bucket profile for precise trenching

Various widths available to match trench requirements

Requires auxiliary hydraulic power for optimal performance

V-Bucket / Trapezoidal Drainage Bucket

V-Buckets excavator attachments are shaped like a “V” and are used for specialized projects, particularly for digging V-shaped trenches where the sides need to remain stable without additional shoring.

Common Uses:

Digging V-shaped trenches

Installing power lines and cables

Creating drainage channels

Features:

V-shaped bucket design for specialized trenching

Helps in reducing the need for extra trench shoring

Requires auxiliary hydraulic power for optimal performance

Riddle Bucket (AKA Shaker or Skeleton Buckets)

Riddle buckets excavator attachments are designed with holes or tines at the bottom and rear of the bucket shell. These holes allow dirt and smaller particles to be sifted out while retaining larger rocks and debris.

Common Uses:

Sorting materials on-site

Separating rocks from soil

Recycling and waste management

Features:

Holes or tines for sifting materials

Reduces need for additional sorting procedures

Requires auxiliary hydraulic power for optimal performance

Tilt Ditching Bucket

Tilt ditching buckets excavator attachments are equipped with a hydraulic cylinder that allows the bucket to tilt side-to-side. This feature enables the operator to create precise slopes and angles without moving the excavator excessively.

Common Uses:

Creating angled banks and slopes

Ditch cleaning with precision

Landscaping industry

Features:

Hydraulic tilting mechanism

Increases efficiency by reducing machine movement

Ideal for complex soil features

Requires auxiliary hydraulic power for optimal performance

Buckets are indispensable excavator attachments, each engineered to enhance the excavator’s capability for a specific task and industry. From the robust digging and rock buckets designed for heavy-duty excavation to the precision of trenching and grading buckets, each excavator attachment is vital for different stages of construction, mining, and landscaping projects. Understanding each type’s specific applications and benefits can help select the right attachment for the job, ensuring efficiency and effectiveness in operations.

Compaction Wheel – Mechanical

These excavator attachments are used to compact the area at the bottom of a trench or in other types of grading and excavating where compacting the soil is required. In some situations where other compaction techniques, like using vibratory machines, are ineffective, compaction wheel attachment can be the only solution available. This is the case when compaction is needed for hard soil or clay. No power is required.

Thumbs

Thumbs are an addition to other excavator attachments that help secure materials by providing a clamping force to hold the material within an attachment, such as a bucket. The thumb would be positioned above the top opening of the bucket, then closed, coming into contact with the contents within the bucket and holding the contents in place. This extends the material handling capabilities. Auxiliary power is required.

Augers

An auger excavator attachment features a hydraulic spiral blade, enabling an excavator to drill and dig holes quickly. Auger attachments are commonly used in construction and landscaping and are an excellent choice for constructing fence posts and building supports. Depending on the complexity of the material that requires holes to be drilled, auger excavator attachments come with different materials.

Standard Bit:

This general-purpose bit can be used for all earth drilling jobs. These excavator attachments are available in different sizes and weight excavators for other purposes. Auxiliary power is required.

Industrial Bit:

This is a professional-grade auger bit attachment that can withstand the grueling daily use of constant drilling. It is the perfect choice when reliability and durability are a must, and delays due to broken and worn-out bits cannot be tolerated. Auxiliary power is required.

Tree Bit:

These excavator attachments are tapered. They have a larger diameter at the top portion and gradually become smaller towards the bottom tip of the bit. They are typically used in landscaping and for drilling holes to plant trees. Auxiliary power is required.

Rock Head Bit:

These bits are the strongest and ideal for drilling into tough materials such as frozen ground, hard compacted soils, clay, and fracturable rock. They are designed with heavy-duty bullet-style teeth capable of making their way through some of the most rigid materials that some might think are impenetrable. Auxiliary power is required.

Hammers

When breaking up hard surfaces such as pavement, concrete, and other hard materials, the hammer attachment is the best choice. It is also well suited for demolition and breaking up rock in a quarry. Hammer attachments are available in different sizes depending on the job requirements and excavator size. A Hydraulic Power Unit (HPU) is required.

Pile Drivers

This attachment, also known as a vibratory hammer, is used for driving posts, pilings, steel sheet piles, and other prefabricated materials into the ground and extracting them from the ground. A Hydraulic Power Unit (HPU) is required.

Rippers

Excellent excavator attachments for tearing through tough materials, rippers are also used for breaking up the frozen ground and demolishing buildings and other structures. Ripper teeth and shanks are designed to penetrate incredibly stout materials and can withstand the most demanding jobs. No power is required.

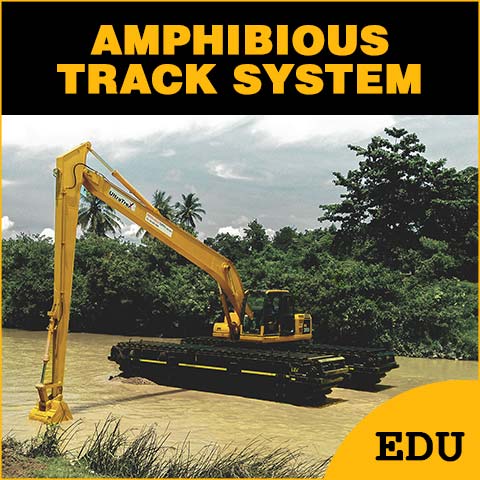

Dredge Pumps

For dredging and removing sediment from rivers, lakes, ponds, and harbors, dredge pumps are the only attachments that can get the job done. Dredge pumps are designed with a cutter head at the inlet of the pump that is used to cut breakaway material at the bottom of a waterway; then pump the material to a floating sectional barge or other floating platforms, or a predesignated area for further processing or disbursement. These pumps can pump substantial solids, and it is tough to pump heavy slurries. These are ideal attachments for standard or amphibious excavators. A hydraulic Power Unit (HPU) is required.

Hydraulic Shears

These attachments are efficient tools for demolishing steel structures and can cut steel plates and girders. Hydraulic shears are an excellent choice for avoiding sparks and flames when shearing and cutting. They can also be used for dismantling automobiles, ships, and airplanes. A Hydraulic Power Unit (HPU) is required.

Couplers

Couplers are an essential component when working with attachments. They affix to the end of the boom/stick assembly and allow a way to quickly and efficiently switch between different types of working attachments without using another person. Couplers can improve versatility; some are designed with automated locking mechanisms that can be operated from within the excavator cab.

Mechanical (manual) Coupler:

This type of coupler directly pins to the boom and has a higher breakout force than pin grabber couplers. Less popular than other types of couplers, these are mostly used on smaller excavators. They offer a tighter fit for attachments and are less costly than hydraulic versions. If the breakout force is greater than what a hydraulic coupler can provide, mechanical couplers would be the best choice. No power is required.

Hydraulic Coupler:

These couplers can be used by a single operator and manipulated from an excavator’s cab. Due to this, they are safer to use than a mechanical coupler. Hydraulic couplers offer greater versatility; the operator can change from one type of attachment to the other with a switch flip. They are also better for larger excavators because of the increased difficulty of changing larger attachments when using manual couplers. Less time spent switching out attachments means more time is needed for the excavator to be used for performing the intended task. Auxiliary power is required.

Tilt Coupler:

These attachments are efficient tools for demolishing steel structures and are capable of cutting steel plates and steel girders. Hydraulic shears are an excellent choice where creating sparks and flames must be avoided when shearing and cutting. They can also be used for dismantling things such as automobiles, ships, and airplanes. Hydraulic Power Unit (HPU) required.

Pin Grabber Coupler:

Pin Grabbers can either be mechanical or hydraulic and are designed with one pin, and a slide that can be fitted to multiple attachment fittings types. It is common for manufacturers to design their excavator attachment with a different geometry where the attachment connects to the coupler. These design of pin grabber couplers are meant to alleviate this issue and can be affixed to any manufacturer’s excavator attachment. Something to consider is that pin grabber couplers can reduce the breakout force of an attachment, resulting in less digging power. Auxiliary power is required.

Mulcher

The mulcher attachment is a powerful and versatile tool that transforms an excavator into a machine capable of handling various land clearing and vegetation management tasks. This attachment is particularly effective for projects that require the ability to mulch trees, shrubs, and other dense vegetation. Mulcher attachments are designed to be durable and efficient, making them a valuable addition to the range of excavator attachments available.

An excavator mulcher attachment is engineered to cut, grind, and mulch trees, brush, and other vegetation into fine mulch. This type of excavator attachment is commonly used in forestry, land clearing, and environmental management projects. The ability to mulch trees quickly and efficiently helps maintain landscapes, prepare land for construction, and manage overgrown areas.

Common Uses:

Land Clearing: Mulcher attachments are ideal for clearing large land areas, making them ready for development or agricultural use.

Forestry Management: These attachments help manage forests by mulching trees and underbrush, promoting healthier vegetation growth.

Right-of-Way Maintenance: Mulcher attachments clear vegetation along roadways, power lines, and pipelines, ensuring accessibility and safety.

Habitat Restoration: By mulching trees and invasive species, mulcher attachments aid in restoring natural habitats and promoting biodiversity.

Features:

Heavy-Duty Construction: Mulcher attachments are built to withstand the rigors of cutting through thick trees and dense vegetation. The robust design ensures longevity and reliability.

High-Powered Performance: These attachments are equipped with powerful motors and sharp blades that can mulch trees efficiently, turning them into fine mulch in minutes.

Versatility: Mulcher attachments can handle various sizes and types of trees, which makes them suitable for different projects and environments.

Hydraulic Drive: Most mulcher attachments are powered by the excavator’s hydraulic system, providing consistent and powerful performance.

Benefits:

Efficient Land Management: The ability to mulch trees and other vegetation quickly reduces the time and labor required for land-clearing projects.

Environmental Impact: Mulching trees on-site recycle organic material back into the soil, enhancing soil health and reducing the need for waste disposal.

Cost-Effective: Using a mulcher attachment can be more economical than traditional land-clearing methods, which often involve multiple pieces of equipment and more labor.

Improved Safety: Mulcher attachments minimize the need for manual tree cutting, reducing the risk of accidents and injuries.

How It Works: The mulcher attachment is mounted on the excavator, transforming the machine into a powerful mulching tool. The attachment’s drum or rotor, fitted with cutting teeth, spins at high speed, shredding and mulching trees and vegetation into small pieces. The excavator’s hydraulic system powers the attachment, ensuring consistent performance and the ability to handle tough materials.

Types of Mulcher Attachments:

Fixed-tooth mulchers: These attachments are designed for heavy-duty applications and can mulch large trees and dense brush.

Swinging Hammer Mulchers: Suitable for lighter vegetation, these attachments use swinging hammers to mulch trees and shrubs, offering flexibility in various environments.

Choosing the Right Mulcher Attachment: When selecting a mulcher attachment for your excavator, consider the following factors:

Size and Power: Ensure the attachment matches your excavator’s size and hydraulic capacity.

Type of Vegetation: Choose an attachment that can handle the specific types of trees and vegetation you need to mulch.

Project Requirements: Consider the scope and duration of your project to select an attachment that provides the best efficiency and performance.

Different Types of Power Sources for Excavator Attachments

Most excavator attachments require only a minimal amount of power for operation. However, some attachments require a greater amount of power, and in some cases, are more powerful than the excavator can provide. In these situations, external power sources are used to ensure adequate power is supplied to the excavator attachment to perform the intended job. This section details the main types of power source options available for powering your excavator attachments.

1. Hydraulic Power

Overview:

Hydraulic power is the most common and widely used power source for excavator attachments. Excavators are typically equipped with hydraulic systems that use pressurized fluid to generate power. This system provides high force and precise control, which is ideal for a range of attachments.

Common Excavator Attachments:

Hydraulic Hammers: These attachments are essential for breaking concrete, rocks, and other hard materials. Their high impact force makes them indispensable in demolition and construction projects.

Hydraulic Shears: Ideal for cutting metal and other materials, hydraulic shears are frequently used in scrap yards, demolition sites, and recycling facilities.

Hydraulic Thumbs: These attachments enhance the machine’s ability to handle and manipulate various materials, which helps with tasks like sorting, loading, and placing objects more efficient.

Advantages:

High Power Output: Hydraulic systems can generate significant force and is suitable for heavy-duty tasks.

Precise Control: The ability to finely control the flow and pressure of hydraulic fluid allows for precise movements and operations.

Wide Compatibility: Hydraulic systems are compatible with a wide range of excavator attachments, enhancing the machine’s versatility.

Disadvantages:

Regular Maintenance: Hydraulic systems need routine maintenance to ensure they operate efficiently, including checking fluid levels and inspecting hoses for leaks.

Potential for Hydraulic Fluid Leaks can occur, leading to environmental concerns and additional maintenance costs.

2. Electric Power

Overview:

Electric power sources are becoming increasingly popular, especially with the rise of electric excavators. These power sources are used for attachments that require less force but benefit from electric power’s clean and efficient nature.

Common Excavator Attachments:

Electric Augers: Used for drilling holes in the ground, electric augers are ideal for planting trees, installing fence posts, and other landscaping projects.

Electric Grapples: These attachments are suitable for handling waste and recyclable materials, offering an environmentally friendly option for material handling.

Advantages:

Environmentally Friendly: Electric power generates no emissions, reducing the environmental impact of operations.

Low Noise Levels: Electric attachments operate more quietly than hydraulic or diesel-powered alternatives, making them suitable for urban areas and noise-sensitive environments.

Reduced Maintenance: Electric systems generally require less maintenance compared to hydraulic systems, with fewer moving parts and no fluid leaks.

Disadvantages:

Limited Power Compared to Hydraulic Systems: Electric power may not provide the same level of force as hydraulic systems, limiting its use in heavy-duty applications.

Dependency on Battery Life or Power Supply: Electric attachments require a reliable power source, whether through batteries or direct electrical connections, which can be a limitation in remote or off-grid locations.

3. Pneumatic Power

Overview:

Pneumatic power systems use compressed air to operate attachments. This type of power source is less common but is used in specific applications where hydraulic or electric power may not be suitable.

Common Excavator Attachments:

Pneumatic Breakers: These are used for breaking up pavement, concrete, and other hard surfaces, similar to hydraulic hammers but powered by compressed air.

Pneumatic Drills: Suitable for drilling in confined spaces or sensitive environments where hydraulic or electric systems may not be appropriate.

Advantages:

Lightweight Equipment: Pneumatic tools are generally lighter than their hydraulic counterparts, making them easier to handle and transport.

Safe to Use in Hazardous Environments: Pneumatic systems do not produce sparks or require electrical power, reducing the risk of explosions in volatile environments.

Disadvantages:

Requires an Air Compressor: An air compressor is needed to generate the compressed air, which can be an additional cost and maintenance requirement.

Less Power Compared to Hydraulic Systems: Pneumatic tools may not provide the same level of force as hydraulic systems, limiting their use in heavy-duty applications.

4. Diesel Power

Overview:

Diesel engines can directly power some large excavator attachments, especially when hydraulic or electric systems are insufficient. Diesel-powered attachments are typically used in heavy-duty applications.

Common Excavator Attachments:

Diesel-Powered Winches: These attachments are essential in construction, mining, and logging operations. They are used for lifting and pulling heavy loads.

Diesel-Powered Pile Drivers: Suitable for driving piles into the ground for foundations, bridges, and other structures.

Advantages:

High Power Output: Diesel engines can generate substantial force, making them suitable for the most demanding tasks.

Suitable for Remote Locations: Diesel-powered attachments can operate independently of external power sources, ideal for remote or off-grid locations where electricity or compressed air may not be available.

Disadvantages:

High Fuel Consumption: Diesel engines consume more fuel than electric or pneumatic systems, leading to higher operational costs.

Increased Noise and Emissions: Diesel engines produce significant noise and emissions, which can be problematic in urban areas or environmentally sensitive sites.

5. Combined Power Systems

Overview:

Some advanced excavator attachments combine power sources to optimize performance and efficiency. For example, a hybrid system might use an electric motor for precision tasks and a hydraulic system for high-force tasks.

Advantages:

Enhanced Versatility: Combining different power sources allows attachments to handle a broader range of tasks efficiently.

Optimized Performance: Hybrid systems can switch power sources as needed, providing the best performance for each task.

Disadvantages:

Complexity in Design and Maintenance: Combined systems are more complex than single-source systems, requiring specialized knowledge for maintenance and repairs.

Higher Initial Cost: The advanced technology and components in combined systems can lead to higher initial costs than traditional systems.

Choosing the right power source for excavator attachments depends on the specific application, the environment, and the required power output. The hydraulic system is the most versatile and powerful, suitable for attachments with most heavy-duty tasks. Electric and pneumatic systems offer cleaner and quieter alternatives for specific applications, while diesel-powered attachments are ideal for the most demanding jobs. Understanding each power source’s advantages and disadvantages can help make an informed decision, ensuring optimal performance and outstanding efficiency in various machine applications.

Conclusion

The wide range of available attachments greatly enhances excavators’ versatility and efficiency. Each attachment type is engineered to handle specific tasks, ensuring that excavators can perform a diverse array of functions with precision and efficiency. By understanding the specific applications and features of each attachment, operators can select the most suitable tools for their projects, leading to improved productivity, cost savings, and high-quality outcomes.

In conclusion, maximizing the capabilities of excavators requires a comprehensive understanding of the various attachments and their appropriate uses. By making informed decisions about which attachments to use and ensuring the right power sources are in place, operators can fully capitalize on the incredible versatility of excavators. This enhances the efficiency and effectiveness of operations and contributes to the great success and profitability of construction, mining, landscaping, and environmental management projects.

Optimize Your Excavator.

How HAWK Excavator Can Help

Considering all of the challenges a construction company faces daily, from project to project, it is critical that your operation be outfitted with the best excavation equipment available.

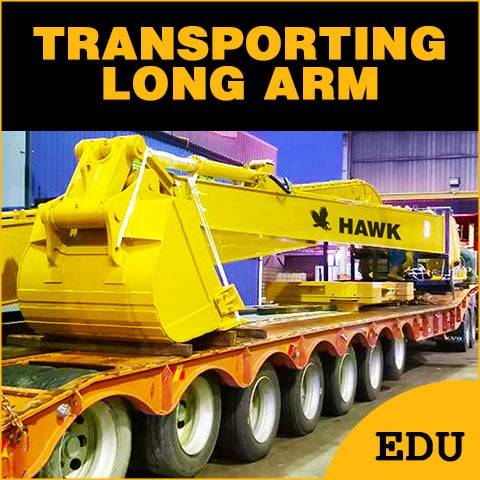

HAWK Excavator is a Manufacturer of Long Reach Excavator Kits, RTK GPS Position Systems, Amphibious Undercarriages, and Modular Barges. We have decades of experience with heavy-duty excavator equipment to enhance and optimize excavation projects worldwide.

Top Product Upgrades for Excavators

- Long Reach Excavator Kits (Stick & Boom)

- HAWK Vision RTK GPS Positioning Systems

- Amphibious Undercarriages

- Sectional Barges

All HAWK products are simple to install to your excavator to assist with a wide range of excavation, construction, and dredging projects.

The top requested product is a conversion from standard to long reach.

For more on the value that HAWK Excavator can provide, Go To: https://hawkexcavator.com/

Articles and Education

Read through our resource library for informational articles that may help you in selecting the right HAWK equipment for the job.