Excavator Deep Hole Digging Applications

Associating excavator drilling equipment, with a focus on Long Reach, for deep hole digging to the different deep hole digging job tasks. HAWK Long Reach go to: https://hawkexcavator.com/products/long-reach-arm-for-excavator/long-stick-excavation/

This Article Includes

- What are the Considerations When Digging Deep Holes with an Excavator?

- Long Reach by HAWK – Ideally Suited for Deep Digging Applications

What are the Considerations When Digging Deep Holes with an Excavator?

For a safe, efficient dig, you want to carefully plan out the job ahead of time. Here are some key considerations while preparing for digging deep holes.

The Location of Your Spoil Pile

Your spoil pile consists of the aggregate you pull out of the ground while digging. Where you put your spoil is crucial because the wrong location could limit mobility, force too many back-and-forth movements during the dig, and even become a safety issue.

Where Existing Utilities Are Located

Identifying the locations of utilities should be one of the first things you do, and it’s best to give yourself at least a week ahead of time to both locate and verify their positions. In some areas, there are services like Dig Safe that will help you find a variety of existing lines and pipes.

Where You Will Stage Pipes and Other Materials

The materials you will be putting in the hole you dug need to be strategically located to enhance the efficiency of your operation. While a distance far from your hole may be easier to identify, the back-and-forth trips to get your materials may hinder efficiency. Ideally, you will want to position all materials within reach of your excavator’s arm.

In addition, if you have to dig multiple holes, you may want to choose at least two locations for your materials. This can cut down on the time it takes to move materials from one digging spot to the next during the job.

Safety

In addition to ensuring workers and observers are kept a safe distance away from dangerous equipment, you want to ensure your excavator and all materials aren’t in danger of dropping into the hole you’re digging in surrounding areas of the landscape. To prioritize safety, you should:

- Perform a detailed site visit, taking measurements and plotting the locations of your excavator, equipment, materials, and spoil.

- Make sure the ground — before, during, and after digging — can support your machinery.

- Ensure you can position your excavator to dig deep enough without sacrificing safety.

Excavator Attachments for Digging Deep Holes

There are several attachments that make the job of deep hole digging easier and faster. Some go-to options include:

- Excavator auger. This is a spiral-shaped tool that pulls out dirt and aggregate as it spins into the ground digging a hole.

- Hydraulic breaker. This breaks through stubborn rock using a striking piston that drives the tip into and through the stone.

- Hydraulic hammer. A hydraulic hammer pummels tough surfaces using multiple strikes per second, dividing and burrowing through obstacles.

Ways to Use a Long Reach Excavator for Deep Digging

With a long-reach excavator, you can maximize the digging depth of the holes, which is roughly 2X the depth achievable with a standard excavator. You can use one for:

- More options for staging materials

- Greater flexibility for the locations of spoil piles

- When operated properly, greater potential for a safer dig

- Achieve digging depths not capable with a standard reach excavator

Increased Digging Precision

With a long stick, you can reach deeper into a relatively small hole without having to make a wider opening. This enables you to dig into tight-fitting situations or anytime space is at a premium. To achieve the greatest precision possible with your digging projects an RTK GPS positioning system can be implemented. RTK GPS is a real-time positioning system that is accurate within an inch of your desired location. This system goes beyond traditional GPS systems in that it also works underwater with the use of a combination of traditional GPS, and Real-time Kinematic positioning (RTK). RTK GPS by HAWK is a combo system where two modular component groupings work in sequence and provide Survey Grade Positioning for an excavator attachment within 1-inch accuracy. Ideal for underwater excavation and dredging and precise deep hole digging, the RTK GPS system first locates the excavator with the use of GPS, then in succession uses the RTK portion of the system to precisely identify the location of the attachment at the end of the excavator boom/stick assembly.

Safer Distances from Deep Holes

If you’re digging in the unreliable ground, it may be safer to increase the distance from the dig location. In some instances, a longer extension can free you up to position your excavator on nearby pavement or other solid foundations instead of right next to the hole. As a result, you may be able to allow workers to move more freely through the site, get materials to the hole quicker, or put them in safer locations.

Increased Flexibility and Efficiency – Your Spoil Pile Location

Using a long arm excavator provides a greater range of options related to where your spoil pile can be located. Having more options regarding where you can locate your spoil pile allows the pile to be positioned in a manner that enables quicker more efficient movement of the excavator, which in turn, can decrease the time required to complete the digging task. The spoil piles can be positioned so that other heavy equipment can operate in the general area of your digging.

Long Reach by HAWK – Ideally Suited for Deep Digging Applications

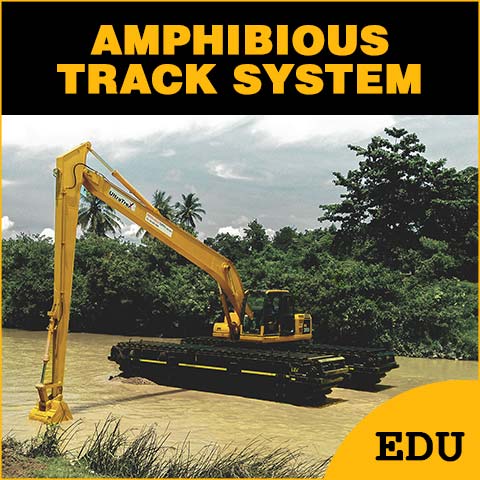

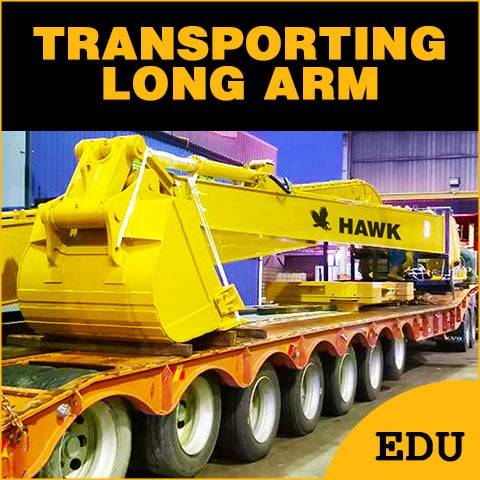

If you find yourself taking on newer and bigger projects outside of the realm of standard excavation, then we highly encourage you to take a serious look at what adding Hawk equipment to your fleet will do for your business. Long reach demolition is a highly specialized business and needs to be treated as such. Renting or leasing big iron will always cost more than owning it, especially when you currently have work or upcoming projects where it will be needed. Owning your own long reach equipment will allow you to tackle an entirely new scope of work from high-end demolition to amphibious excavation.

Optimize Your Excavator.

How HAWK Excavator Can Help

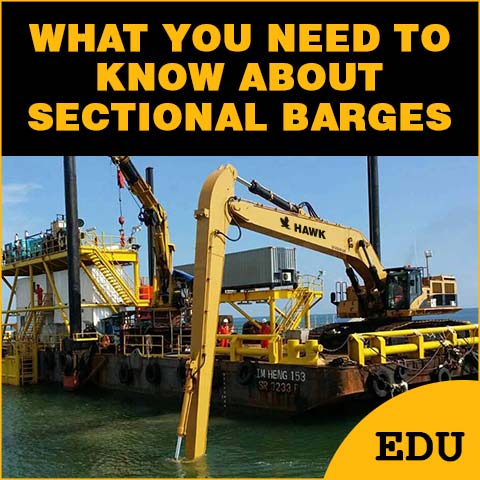

HAWK Excavator is a Manufacturer of Long Reach Excavator Kits, RTK GPS Position Systems, Amphibious Undercarriages, and Modular Barges. We have decades of experience with heavy-duty excavator equipment to enhance and optimize excavation projects worldwide.

Top Product Upgrades for Excavators

- Long Reach Excavator Kits (Stick & Boom)

- HAWK Vision RTK GPS Positioning Systems

- Amphibious Undercarriages

- Sectional Barges

All HAWK products are simple to install on your excavator to assist with a wide range of excavation, construction, and dredging projects.

The top requested product is a conversion from standard to long reach.

For more on the value that HAWK Excavator can provide, Go To: https://hawkexcavator.com/

Articles and Education

Read through our resource library for informational articles that may help you in selecting the right HAWK equipment for the job.

Frequently Asked Questions

What types of digging equipment are suitable for deep-hole digging applications?

Specialized digging equipment is essential for deep hole digging applications to ensure efficient and precise excavation. Common types of digging equipment suitable for deep hole digging include augers, rock drills, trenchers, and hydraulic breakers. These attachments are designed to penetrate various soil types, rocks, and obstacles to excavate deep holes accurately and efficiently.

How do I choose the right machinery for my deep hole project?

Choosing the right digging machinery depends on factors such as the diameter and depth of the hole, the type of soil or rock to be excavated, and the space constraints of the work site. For example, augers are ideal for drilling narrow holes in soft to moderately compacted soils. In contrast, rock augers are designed for drilling through challenging rock formations. Hydraulic breakers are suitable for breaking up concrete or rock surfaces to prepare for excavation. Our team can provide personalized recommendations based on your project requirements and the capabilities of different digging equipment.

Can digging equipment be used with different sizes of excavators for deep hole digging?

Yes, digging equipment can be used with excavators of different sizes to accommodate various deep-hole digging applications. Whether you have a compact mini excavator or a large hydraulic excavator, digging attachments are available to suit your machine. It’s essential to ensure that the digging equipment you choose is compatible with your excavator’s weight, hydraulic flow, and mounting configuration for safe and efficient operation.

What maintenance is required for digging attachments and machinery in deep-hole applications?

Regular maintenance is crucial for keeping digging attachments and machinery in optimal condition for efficient operation in deep-hole applications. Before each use, inspect attachments for signs of wear, damage, or hydraulic leaks and address any issues promptly to prevent further damage or safety hazards. Lubricate grease fittings, hydraulic hoses, and pivot points according to the manufacturer’s recommendations. Proper storage in a clean, dry environment when not in use can also help prevent corrosion and deterioration.

Can digging equipment for deep hole digging be rented or purchased?

Digging equipment for deep hole digging can be rented or purchased depending on the duration and frequency of use and budget considerations. Renting equipment is a cost-effective option for short-term projects or occasional use, while purchasing may be more economical for long-term or frequent use. Our team can guide you on the best option for your specific requirements and help you select the right digging equipment for your deep hole project.

How do I ensure safe operation when using machinery for deep hole digging?

Safety is paramount when operating digging machinery for deep hole digging. Before starting work, familiarize yourself with the operation and safety guidelines outlined in the equipment manual. Always wear appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, gloves, and steel-toed boots. Follow proper excavation techniques and never overload or exceed the capacity of the equipment. Regularly inspect the machinery for wear or damage, and discontinue use if any issues are detected. Our experts can provide training and guidance on safe operating practices to minimize the risk of accidents or injuries.