Modular Pontoon Floats

For Barges and Floating Platforms

Build any pontoon platform to fit the needs of your project. Completely modular, lightweight, and combined with the ease of shipping, makes our sectional barges and floating platforms an easy solution for barge construction projects.

Reliability

Designed to be containerized and truckable for land transportation and rapid deployment. Durable enough to hold heavy equipment for industrial dredging projects.

Modular Design

Interlocking System

Interlocking system for quick setup on the jobsite to whatever size barge is needed for the project. Ability to expand as needed.

What’s a Sectional Barge?

Excavator Mounted Sectional Barge and Floats are specially designed to perform excavation and dredging activity on deepwater areas. Our well-designed excavator-mounted sectional barge equipped with paddlewheel/ marine hydraulic thruster shall provide great mobility and this propulsion system enables the machine to move effectively from shallow to deep water. HAWK excavator mounted sectional barge can be easily mobilized or transported by truck and this helps our customer’s dredging projects on the inland rivers and lakes.

What’s Included?

The HAWK Excavator Barge System is a modular platform capable of supporting excavators for both hydraulic dredging using slurry pumps or traditional mechanical dredging with clamshells. Let us know your project for further details.

Hydraulic Dredging

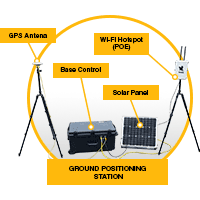

Attach the RTK / GPS Positioning system to your hydraulic or electric powered dredge pump to always know where the suction head is under the waterline.

Mechanical Dredging

Attach the RTK / GPS Positioning system to your excavator’s bucket or other attachment to always know where the bucket is under the waterline..

HAWK Related Products

Check out our full line of excavator accessories designed to aid with a wide variety of construction and excavation, including dredging.

HAWK Vision

Attach the RTK / GPS Positioning system to your excavator’s bucket or other attachment to always know where the bucket is under the waterline..

Amphibious Undercarriage

Complete amphibious undercarriage allowing you to convert your existing excavator into a swamp dredger capable of even more production in harsh areas.

Long Reach Excavator Arms

Our Long Reach Arm package is available for a wide range of excavator models according to the customer’s exact needs.

Reach Beyond, with HAWK.

Efficient Excavation saves YOU money.

Rent Equipment Shown. The Only place to Rent Long Reach Fronts

Frequently Asked Questions

What are barge floats, and how are they used with excavators?

Barge floats, or sectional barges or float barges, are modular floating platforms used to support excavators and other heavy equipment for marine construction, dredging, and material handling operations. These floats are typically assembled from individual sections, allowing effortless transportation and customization to suit different project requirements.

What are the advantages of using barge floats with excavators?

Using barge floats with excavators offers several advantages, including increased mobility and accessibility to water-based work sites. Barge floats provide stable platforms for excavators to operate from, allowing them to reach areas inaccessible from land or inaccessible with conventional equipment. Additionally, barge floats can be configured with various attachments and accessories to enhance the versatility and functionality of the excavator for marine applications.

How do I choose the suitable barge floats for my excavator?

Choosing the suitable barge floats depends on factors such as the excavator’s size and weight, the water’s depth, and the project’s specific requirements. Considerations such as buoyancy, stability, and load capacity are essential when selecting barge floats to ensure safe and efficient operation. Our team of experts can assess your project needs and recommend the most suitable barge floats to complement your excavator and meet your marine construction or dredging requirements.

Can barge floats be customized to accommodate different excavator sizes and configurations?

Barge floats can be customized to accommodate different excavator sizes, configurations, and attachment requirements. Modular sectional barges can be assembled in various configurations to provide stability and support for excavators of different weights and sizes. Additionally, barge floats can be equipped with crane pads, railing systems, and equipment tie-downs to enhance safety and functionality.

Are barge floats available for rent or purchase?

Barge floats are available for rent and purchase, depending on the duration and frequency of use and budget considerations. Renting barge floats is a cost-effective option for short-term projects or occasional use, while purchasing may be more economical for long-term or frequent use. Our team can provide guidance on the best option for your specific requirements and help you select the suitable barge floats for your excavator and marine construction or dredging project.

What maintenance is required for barge floats and excavators used in marine applications?

Regular maintenance is essential for keeping barge floats and excavators in optimal condition for safe and efficient operation in marine environments. Inspect the equipment regularly for signs of wear, corrosion, or damage, and address any issues promptly to prevent further deterioration. Clean the machine thoroughly after each use to remove debris, mud, and vegetation that may accumulate in the tracks or components. Lubricate moving parts and components according to the manufacturer’s recommendations to ensure smooth operation and minimize the risk of corrosion in wet conditions.