Home /

Hydraulic Breaker Hammer

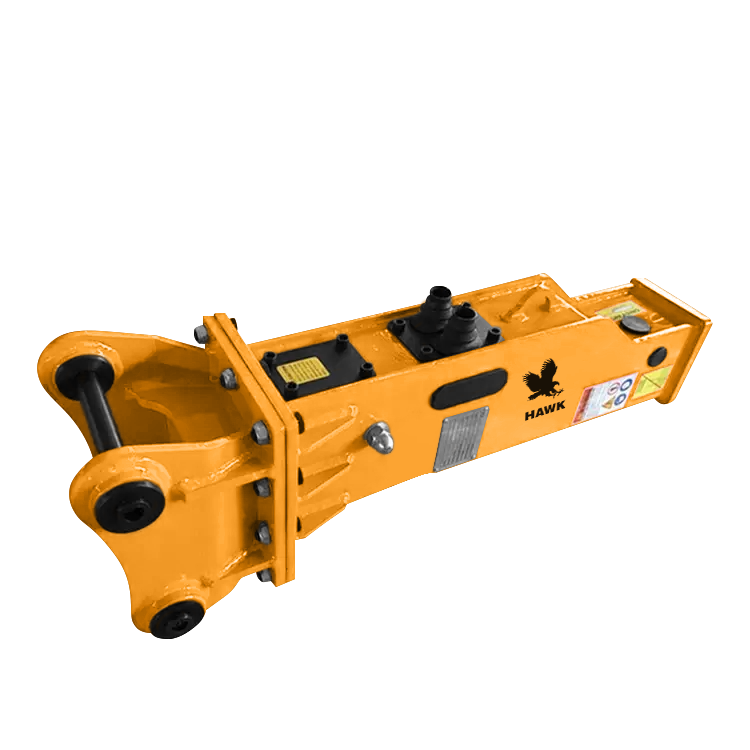

The HAWK Excavator hydraulic breaker hammer is an industry-leading demolition and construction tool renowned for its exceptional performance and versatility. This range of hydraulic breakers includes the HAWK top hydraulic breaker hammer, HAWK side hydraulic breaker hammer, and HAWK box breaker hammer, each designed to meet specific job requirements with precision and power.

HAWK hydraulic breaker hammers are engineered to deliver high-impact energy, making quick work of demanding tasks such as concrete and rock demolition, asphalt removal, and trenching. Their rugged construction ensures durability even in the most challenging environments, making them indispensable for professionals in the construction and demolition sectors.

The HAWK top hydraulic breaker hammer is ideal for overhead and horizontal applications, offering precise control and power for tasks requiring finesse. The HAWK side hydraulic breaker hammer is designed for vertical and inclined surfaces, allowing operators to tackle walls and other upright structures efficiently. Meanwhile, the HAWK box breaker hammer excels in confined spaces and tight quarters, ensuring every job is easy to handle.

In summary, HAWK breaker hammers are the go-to choice for contractors and builders who demand superior performance, reliability, and adaptability in demolition and construction projects. With their range of specialized models, HAWK breaker hammers are the ultimate tools for achieving optimal results in various work scenarios.

Excavator Tonnage: 1-40 Ton

Type: Top, Side, Box (Noise Reducer)

Chisel Options: Moil point, Blunt, Flat chisel, Conical point

Applications: Break up concrete, rock, and other hard materials

HAWK Hydraulic Breaker Hammers

Top Breaker Hammer

The HAWK Excavator Top Breaker Hammer is a specialized hydraulic demolition tool designed for precision work on horizontal surfaces. It offers high-impact energy and precise control, making it ideal for tasks that require finesse, such as concrete slab removal and pavement breaking. The breaker hammer’s ergonomic design and powerful performance make it a top choice for professionals in the construction and demolition industries when working on flat or slightly inclined surfaces.

Side Breaker Hammer

The HAWK Excavator Side Breaker Hammer is a hydraulic demolition tool engineered for vertical and inclined surfaces. This specialized equipment provides exceptional power and control, perfect for breaking down walls, columns, and other upright structures. Its design allows for efficient and precise work in scenarios where horizontal tools may be less effective. It’s a preferred choice among construction and demolition professionals when tackling tasks that require working on vertical or inclined surfaces.

Box Breaker Hammer

The HAWK Excavator Box Breaker Hammer is a compact and versatile hydraulic demolition tool for confined spaces and tight quarters. It delivers high-impact energy while maintaining precision and control, making it perfect for tasks in cramped environments where larger equipment cannot access. This specialized breaker hammer from HAWK Excavator is an essential choice for professionals working in restricted spaces, ensuring efficiency and effectiveness in various demolition and construction applications.

Benefits of Hydraulic Breaker Hammers

Exceptional Power: HAWK Excavator Hydraulic Breaker Hammers are renowned for their high-impact energy output, allowing them to break through rigid materials like concrete and rock. This power translates to faster and more efficient demolition and construction work.

Versatility: HAWK offers a range of breaker hammer models, including top, side, and box breakers, catering to various job requirements and work environments. This versatility ensures that professionals have the right tools for any task.

Precision Control: Operators benefit from precise control over the force and impact of the hammers. This accuracy is crucial when working on delicate structures or when finesse is required.

Durability: HAWK Breaker Hammers are built to withstand the rigors of construction and demolition. Their robust construction ensures longevity, reducing downtime and maintenance costs.

Safety Features: These hammers are equipped with safety features to protect operators and prevent accidents on the job site. Safety is a top priority, enhancing the overall work environment.

Ease of Maintenance: Designed for easy maintenance, HAWK hammers minimize downtime and reduce repair costs. This ensures that professionals can keep their equipment in peak working condition with minimal effort.

Efficiency Boost: HAWK Hydraulic Breaker Hammers increase productivity by completing tasks faster and more precisely. This efficiency directly translates to cost savings and improved project timelines.

Adaptability: Whether it’s large-scale demolition or detailed excavation work, HAWK hammers adapt to various job requirements, making them indispensable tools for professionals in the construction and demolition industries.

Cost-effectiveness: The combination of efficiency, durability, and reduced maintenance needs makes HAWK Hydraulic Breaker Hammers a cost-effective choice over the long term, contributing to overall project cost savings.

Industry Trust: HAWK is a trusted brand known for reliability and performance. Professionals worldwide rely on HAWK hammers to do the job effectively and efficiently.

Features of Hydraulic Breaker Hammers

HAWK Excavator hydraulic breaker hammers are known for their reliability, durability, and high-performance capabilities in construction and demolition. These powerful tools are essential for breaking through rigid materials like concrete, rock, and asphalt. Here are some essential features that make HAWK hydraulic breaker hammers stand out:

High Impact Power: HAWK hydraulic breakers deliver exceptional impact power, allowing them to break through even the most rigid materials efficiently. This high-impact power is crucial for increasing productivity on construction sites.

Durable Construction: These hammers are built to withstand the rigors of heavy-duty work. They are constructed with high-quality materials and precision engineering, ensuring long-lasting performance even in demanding conditions.

Easy Maintenance: HAWK hydraulic breakers are designed with user-friendly maintenance in mind. They often feature a simple, modular design that makes it easy to access and replace worn parts, reducing downtime and maintenance costs.

Adjustable Settings: Many HAWK hydraulic breakers have adjustable settings, allowing operators to control the impact force and frequency. This adaptability makes them versatile and suitable for a wide range of applications.

Noise and Vibration Reduction: HAWK hydraulic breakers have features to minimize noise and vibration levels to enhance operator comfort and safety. This helps reduce operator fatigue and potential health hazards associated with prolonged exposure to vibrations.

Compatibility: HAWK hydraulic breakers are often designed to be compatible with various carriers, including excavators and skid-steer loaders. This versatility allows contractors to use the same breaker on different equipment, maximizing their investment.

Safety Features: Safety is a top priority in construction, and HAWK hydraulic breakers typically incorporate safety features like auto-shutoff systems to prevent accidents in case of malfunctions or operator errors.

Wide Range of Models: HAWK offers various hydraulic breaker models with different sizes and specifications, ensuring contractors can find the right tool for their job requirements.

HAWK hydraulic breaker hammers are characterized by their robust construction, powerful performance, ease of maintenance, and safety features. These qualities make them valuable tools for various construction and demolition projects, where efficiency and reliability are paramount.

Frequently Asked Questions (FAQs) – Hydraulic Breaker Hammer Attachments

What are hydraulic breaker hammers, and how do they work?

Hydraulic breaker hammers are powerful demolition tools used in construction and mining industries to break through hard materials like rock, concrete, and asphalt. They use hydraulic pressure to deliver repeated blows to the surface, breaking it apart.

What are the key benefits of using hydraulic breaker hammers on construction sites?

Hydraulic breaker hammers offer several advantages, including increased productivity, reduced labor costs, precise and controlled demolition, versatility in handling various materials, and minimized environmental impact compared to traditional methods like explosives.

What factors should I consider when choosing a hydraulic breaker hammer for my project?

When selecting a hydraulic breaker hammer, factors such as the size and type of material to be demolished, the required impact energy, carrier compatibility, operating weight, and noise levels should be taken into account. Consulting with a heavy equipment expert can help determine the most suitable breaker for your needs.

What are the key differences between top-mounted, side-mounted, and box hydraulic breaker hammers?

Top-mounted hydraulic breaker hammers are attached to the excavator’s boom, providing vertical impact force for breaking through materials. Side-mounted hammers are attached to the side of the excavator’s arm, offering lateral impact force, while box hydraulic breaker hammers are enclosed for noise reduction and are versatile for various applications.

What factors should I consider when choosing between top-mounted, side-mounted, or box hydraulic breaker hammers?

Consider the specific requirements of your project, including the type of material to be broken, the space available on the job site, and any noise restrictions. Top-mounted hammers are ideal for vertical demolition tasks, while side-mounted hammers offer increased flexibility for accessing tight spaces. Box hydraulic breaker hammers are suitable for noise-sensitive environments and provide versatile performance.

How do I determine the compatibility of a hydraulic breaker hammer with my excavator?

Ensure that the hydraulic breaker hammer is compatible with your excavator’s hydraulic system, weight capacity, and mounting configuration. Consult the manufacturer’s specifications and recommendations to verify compatibility and ensure proper installation and operation.

What are the advantages of using a box hydraulic breaker hammer for noise-sensitive environments?

Box hydraulic breaker hammers are equipped with specialized enclosures that minimize noise levels during operation, making them suitable for use in urban areas, residential neighborhoods, and other noise-sensitive environments. They help mitigate noise pollution while maintaining efficient performance and productivity.

Can hydraulic breaker hammer attachments be used for tasks other than demolition and breaking?

Yes, hydraulic breaker hammer attachments are versatile and can be used for various applications, including excavation, trenching, landscaping, and road construction. They provide efficient and precise breaking, cutting, and material handling capabilities, enhancing the versatility and productivity of excavators.

What maintenance procedures are required for hydraulic breaker hammer attachments?

Regular maintenance is essential to ensure optimal performance and longevity of hydraulic breaker hammer attachments. Maintenance procedures may include inspecting hydraulic hoses and connections, lubricating moving parts, checking for wear on wear components, and ensuring proper hydraulic fluid levels and pressures. Follow manufacturer guidelines and recommendations for specific maintenance intervals and procedures.

Can hydraulic breaker hammer attachments be rented or leased instead of purchased?

Yes, many equipment rental companies offer hydraulic breaker hammer attachments for short-term rental or long-term lease. Renting or leasing can be a cost-effective option for contractors who have occasional or temporary need for hydraulic breaker hammer attachments, providing flexibility and cost savings compared to purchasing outright.

What safety precautions should I follow when operating a hydraulic breaker hammer attachment?

Operators should undergo proper training and certification to operate hydraulic breaker hammer attachments safely. Follow all manufacturer guidelines and safety protocols, including wearing appropriate personal protective equipment (PPE), maintaining a safe distance from the attachment during operation, and adhering to recommended load capacities and operating parameters. Regular equipment inspections and safety checks should also be conducted to ensure safe and reliable operation on the job site.