Trenching and Excavation Safety Tips

This Article Includes

- Trench Shoring with Long Reach Excavation

- How to spec long reach units for Trenching

- Tips for safe long reach operation

Long Reach Excavator Safety – Trenching

Long reach excavation comes with many inherent risks when it is your job to disrupt and remove high volumes of earth, water, and sections of the job site environment. If you are running a top-heavy long reach unit without counterweights or stabilizing outriggers your job may be compromised before you even start.

When Do You Need Trenching to Accompany Excavation Projects?

High-reach excavators are required for high-profile demolition projects, and controlled construction, and are essential for underwater dredging and amphibious excavation. Trench shoring is an industry-standard requirement when digging depths exceeding 5 or more feet unless you are digging solid rock. Trench box requirements are mandated by OSHA and determined by project managers and engineers before work begins.

Trench shoring ensures the safety of the job site, all employees, and the actual integrity of the environment you are working in regardless of the scope of excavation. Trench shoring minimizes soil shifting during excavation and promotes a more controlled dig. Shoring also mitigates the risks of hitting gas lines and other existing utility lines. Trench collapses are serious risks whether you are working on dry land moving dirt or dredging ponds that may have potential sinkholes. Working in a controlled manner must be the priority of all operators and job site management.

ADDITIONAL Information: https://www.osha.gov/sites/default/files/publications/trench_excavation_fs.pdf

Can Any Operator Run a Long Reach?

Running your long-reach excavator requires expert operators. There is no way around it. This individual must possess an incredible amount of skill, awareness, and experience to ensure proper use and productivity. With virtually double the range of motion as a standard excavator, the operator needs to be aware of all environmental hazards such as electrical lines, underground utility lines, and everyone working around them. Virtually all heavy equipment operating safety standards apply but are amplified due to the increased size of the unit and inherent risks of misuse or negligence.

Am I Running the Proper Long Reach For My Scope of Work?

This falls on project managers and operators to properly scope the job and the required equipment. Misusing equipment or guessing what you need can become a recipe for disaster. Overshooting the specs on a long-reach unit that may be a little under what is required for the job runs the same risk of feeling too comfortable in an oversized unit.

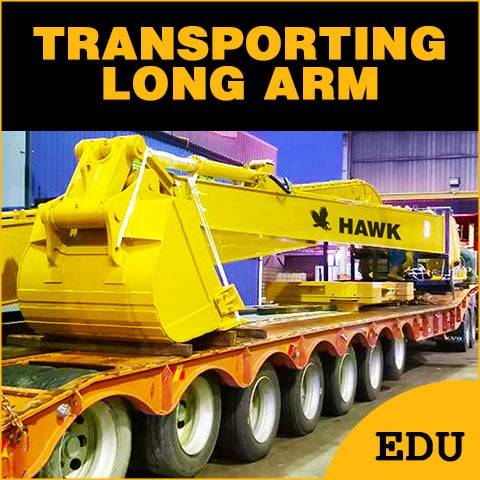

It cannot be overstated how essential scaling your equipment needs are and ensuring they are aligned with the exact scope of work. Misusing equipment can cause compromised hydraulic lines, oil lines, cables, tracks, and controls on the unit and endanger you and everyone on the job. If you have any questions regarding Hawk specifications please contact us directly and refer to our equipment spec sheets on our resources page.

What Attachments Can My Long Reach Run and What is Overloading?

Running your long-reach excavator requires expert operators. There is no way around it. This individual must possess an incredible amount of skill, awareness, and experience to ensure proper use and productivity. With virtually double the range of motion as a standard excavator, the operator needs to be aware of all environmental hazards such as electrical lines, underground utility lines, and everyone working around them. Virtually all heavy equipment operating safety standards apply but are amplified due to the increased size of the unit and inherent risks of misuse or negligence.

What Makes Long-reach Excavation Safer and More Efficient?

Long reach excavation is very safe and very efficient when done properly. Firstly, you do not want to run your long-reach excavator in soft sand, deep mud, or on inclined/sloping hills. If the base and balance of the unit are compromised you will not be able to conduct the work that is required. You want to make sure your counterweighting is able to support the now top-heavy oversized boom plus any attachments you are running. Stabilizing outriggers in addition to counterweights may be required depending on the job.

Long-reach excavators are also a great alternative to traditional demolition methods. They provide an exponentially more controlled system as opposed to wrecking balls and controlled explosion demolitions in heavily populated areas. A long-reach excavator is a much more effective and safer alternative than sending labor crews with oxy-propane torches to cut structural beams. You can save manpower and mitigate job site safety risks in one fell swoop.

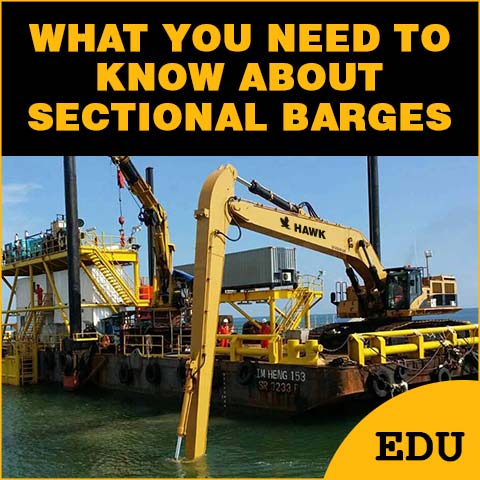

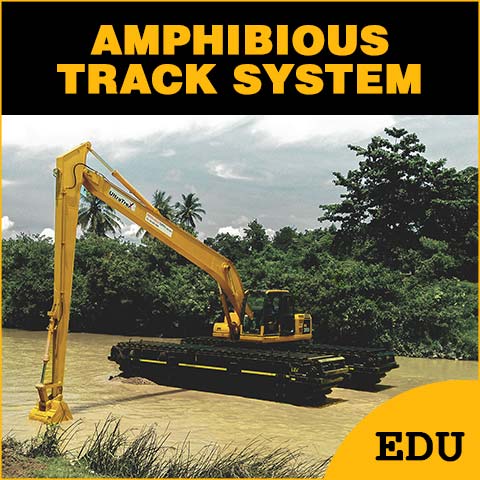

The same principles apply when you are running amphibious long-reach excavators. Specialized tracks ensure that you maintain a strong base to dig, dredge, and move the earth. And if you are working on water, hermetically sealed pontoon tracks allow you and your long-reach excavator to dig where you need to. Still equipped with counterweights and whatever attachments you need, you can dredge, landscape, manage erosion prevention, deepen waterways, and clean out river beds. Whether you are on water or wet, uneven swampland, HAWK’s pontoon tracks grant you the full functionality of long-reach excavators in the toughest environments.

Things to Consider (Pro-Tips)

- Select the right boom configurations that are within your scope of work for the jobs you are looking to bring on. Are you running long-reach excavators for demolition work or for amphibious excavation?

- Factory-built versus aftermarket. Are you converting an existing unit with more long-term utility into a long reach unit or are you looking for a ready-made long reach unit? This is very important to consider when it comes to maintenance, parts, safety, and warranty claims.

- Design differences. Boom configurations are paramount in the long-reach excavation industry. But what about your undercarriage? Do you need a retractable undercarriage? What about a hydraulic extendable undercarriage if you are running an aftermarket long reach excavator versus a factory-made long reach? Scoping your track frames and undercarriage needs is essential.

Hawk Excavation places an emphasis on job site safety, efficiency, and increasing productivity. Our products are designed with integrity, functionality, and with an emphasis on field reliability.

Articles and Education

Read through our resource library for informational articles that may help you in selecting the right HAWK equipment for the job.