How to Choose an Excavator

This Article Includes

- What is an Excavator?

- 5 Primary Excavator Selection Considerations

- Primary Industries Where Excavators are Used

What is an Excavator?

Excavators are classified as heavy equipment and can be used for a multitude of jobs that require digging, grading, dredging, material handling, and many other tasks. They are the most common piece of heavy equipment on construction sites and are available in many different types and sizes. They are capable of maneuvering through many different types of terrain. Most excavators consist of a boom and stick, bucket or other stick attachment, a cab that rotates and that sits atop of a platform that is fitted with either tracks or wheels for moving around the job site. They use hydraulic fluid, hydraulic cylinders, and hydraulic motors to lift extremely heavy loads. The hydraulic system is powered by a diesel motor, or if greater power is required a hydraulic power unit (HPU) that is either affixed to the excavator or an external unit can be used.

Incredibly versatile, the more common excavators are considered standard, while others are designed for specialized situations which can include scaling steep hillsides, working in waterways such as harbors, swamps, and wetlands, or operating in situations where precision and safety are critical factors.

Making the decision as to which excavator to buy or rent can be somewhat complicated. Especially when companies are trying to persuade the customer to purchase “their” excavator vs a competitor’s product that might be better suited for your needs. Although there can be a number of factors as to why to purchase or rent a specific excavator, the key point on which types and size to choose should be based on what, where, and how the excavator will be used. Subjects such as cost, are certainly important, but the excavator must be well suited for the job and intended task to be performed. The following information provides a general understanding of the primary considerations that can be used when deciding what excavator is best for your needs. These considerations are only suggestions, and where multiple types of excavators can be used for the same task, other factors not listed in this article can be beneficial. For more information on the different types of excavators and the jobs, they can perform, check out our Excavator Types 101 article.

5 Primary Excavator Selection Considerations

1. Worksite Environment

2. Job Being Performed

3. Lifting Capacity Required

4. Type of Excavator

5. Excavator Size

Worksite Environment

Dryland or waterway

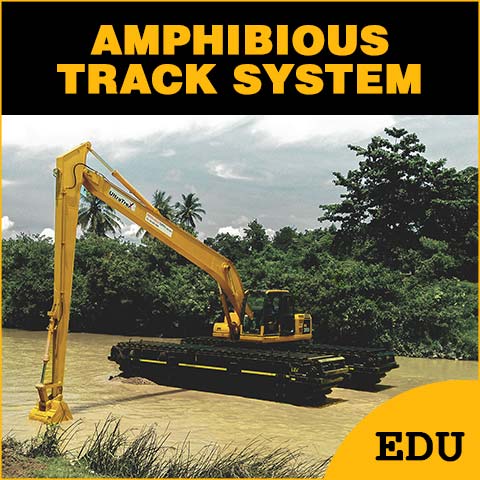

When choosing what type of excavator to purchase, one of the most important questions is where will the equipment be used – either land or water. This is a key factor because excavation occurs in different types of environments, whether it be dry land, soggy water-laden marshlands, or waterways such as rivers, lakes, and harbors. If the environment that which the excavator is to be used is dry land perhaps an excavator fitted with tracks or wheels is most appropriate, but if the environment is a waterway then an excavator with amphibious capabilities could be the best choice.

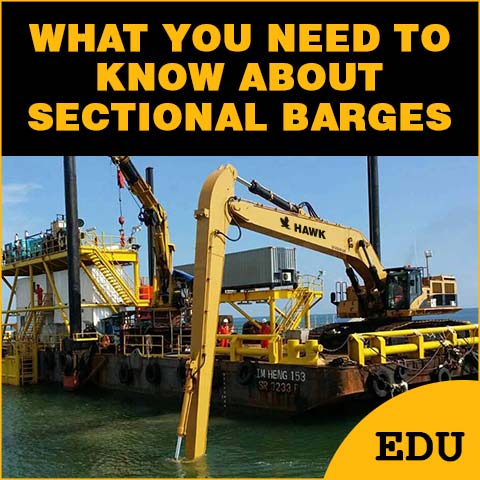

As a perfect accompaniment to amphibious excavators are sectional amphibious barges. Amphibious barges are used to transport large volumes of material that are removed by the excavator. Once the barge is filled to capacity, it transports the material to the desired location so that the barge can be off-loaded. Amphibious barges are designed with paddle wheels and hydraulic thrusters that propel the barge through the water. They can be used in shallow or deeper water and are an essential part of a dredging operation.

Ground Structure

Another consideration pertaining to the environment is ground structure. Is the ground structure that the excavator is to be used soft or unable to support the heavyweight of the machine? Is the ground structure hard and compact, or a surface that can be damaged such as a pre-graded finished dirt surface for building structures, or an asphalt surface that is susceptible to damage by a tracked vehicle? These are important questions because there are options related to how an excavator comes into contact with the ground surface that the machine will be used.

For softer surfaces such as sand or loose gravel, an excavator with tracks can be the best choice for the job. In an environment where the surface is hard or made of a material that might become damaged from a tracked vehicle, a wheeled excavator can be the appropriate selection.

Extreme Terrain

For extreme terrains such as sloped hillsides and remote locations, there are excavators such as spider (AKA walking) excavators that are specifically designed for use in these types of environments. These types of machines can traverse areas where maneuvering an excavator could be considered impossible.

Environments Requiring Precision and Safety

For environments that require precision, or where safety is critical, there are excavator accessories that can provide GPS positioning so that the excavation attachment only comes in contact with the specific area to be excavated or graded. This type of equipment can be of particular value when working around underground piping and cables that cannot be damaged.

Job Being Performed With an Excavator

The task that you need to accomplish is one of the most important considerations. If an excavator is purchased or rented that does not meet the needs of the job you require, time and money are wasted and the job is not adequately accomplished or is not conducted at all. Delays in schedule resulting from having the wrong equipment can cause issues with completing the entire project when required, whether it be new building construction, harvesting crops on time, or dredging a harbor to allow for the safe and efficient passage of cargo ships.

List of Major Functions of an Excavator:

- Grading: Is one of the most challenging tasks that require the greatest accuracy.

- Digging: Is the most popular task, one of the most wide-ranging, and buckets are the most popular attachment used.

- Trenching: Is required for installing the pipeline, building footings and can be as deep as 15-feet or more.

- Dredging: Is used for removing sediment from rivers, lakes, ponds, and harbors to allow passage for boats and ships. This job is accomplished with a dredge pump attachment and an amphibious excavator.

- Material Handling: Involves transferring or moving any materials from one location to another that can be moved with an excavator.

- Demolition: Is very dangerous and is used for dismantling, or destroying any building or structure.

- Hammering: Is used for breaking up roadways and cement, ice, and any other demolition at ground surface level.

- Pile Driving: Refers to installing vertical sheets of steel, or wood or metal posts into the ground.

- Drilling: Is used for making holes to install fence posts, building supports, and drilling into rock and cement.

- Shearing: Is common in the demolition of buildings and cutting metal girders.

- Ripping: Is used for breaking up frozen ground or demolishing structures and roadways.

- Removing Vegetation: This is a task that can be performed for many reasons; a popular method is using an amphibious excavator with a rake attachment to scrape vegetation from the surface of a waterway.

Breakout Force and Lifting Capacity Required

An essential factor regarding the maximum power that can be exerted at the attachment of an excavator is breakout force. The greater the breakout force means more digging and lifting power. Most manufacturers publish the breakout force associated with their excavators. Attachments that extend the boom/stick assembly have the potential to reduce the breakout force of the excavator.

Lifting capacity is a combination of hydraulic lifting force and the machine’s stability or tipping load. Some common factors for determining lifting capacity also include boom length, stick length, counterweight, bucket size, and circuit pressures (both working and holding). A common practice is to not exceed 87 percent of the hydraulic lifting force, and 75 percent of the tipping load tested. Lifting capacity is a very important aspect of using an excavator, and surpassing the hydraulic lifting force and tipping load can cause injury or death. NOTE: This information is to be used as a general reference only, and the percentages for hydraulic lifting force and tipping force could change depending on your specific situation and machine.

List of Excavator Types and Uses

- Standard or Crawler: One of the most popular and designed for most excavation jobs. Tracked and ideal for working on soft terrain.

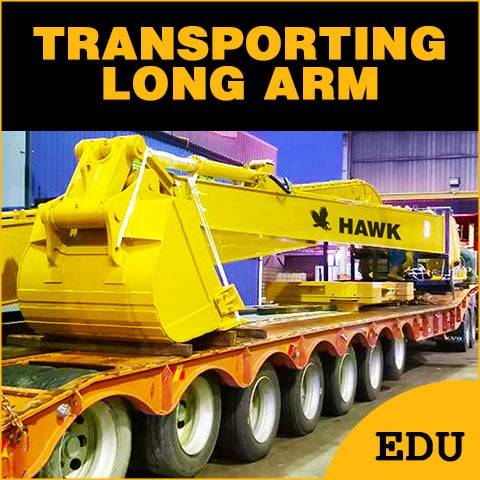

- Long Reach: These can be either wheeled or tracked and allow increased ability to reach further distances. Standard reach excavators reach up to 40 feet, and long reach up to 100 feet; long reach has the reaching capability 2X times greater than standard reach.

- Wheeled: Better suited for operation on hard surfaces such as concrete and asphalt. Easier to maneuver and can move about a worksite at faster speeds. Increase the potential of completing jobs in a shorter period of time.

- Spider or Walking: One of the most unique and looking, they are designed with spider-like legs that can operate independently. Designed for specialized situations that require it to maneuver on extremely steep hillsides, and challenging terrains.

- Knuckle Boom: Designed with an extra joint on the boom/stick assembly allows the stick and bucket to rotate from side to side, which increases maneuverability in tight spaces and around obstacles.

- Amphibious: Designed to be used in wet environments, they are used for dredging and removal of sediment and debris at the bottom of rivers, ponds, lakes, harbors, and other waterways. They can operate in wetlands and water up to 6-ft. deep. They are usually fitted with either a bucket or dredge pump at the tip of the boom/stick assembly.

- Backhoe: Can perform multiple tasks without having to switch out boom attachments as often because it is designed with a boom/stick/bucket assembly on one end, and a bucket on the other. Capable of moving larger volumes of materials than standard excavators.

- Hydraulic Shovel: Hydraulic shovels are heavy-duty and designed for very extreme lifting and digging. They can haul large rocks, soil, and other materials that are too heavy for other types of machines.

- Demolition: Used for dismantling or destroying buildings, industrial structures, and any other structure that requires demolition. Designed with special guards for the cab and windows to protect the operator from falling debris

- Vacuum Truck or Suction: Used in situations that require precision removal of material without damaging surrounding infrastructure. Constructed with a high-pressure vacuum and water jets used to loosen and precisely draw material into a holding tank.

- Skid Steer: Very common at construction sites, used for cleaning debris from job sites, and working in areas where space is limited; very maneuverable.

Excavator Sizes

Mini-Size (less than 7 tons)

- Perfect for small tight jobs, offers greater precision than larger excavators. Not as powerful and less lifting capacity than larger machines.

Mid-Size ( 7 to 10 tons)

- Good choice for small spaces but require more reach and power than a mini excavator. Good maneuverability but still big enough for building construction projects.

Standard Size (10 to 45 tons)

- The most common size, they provide sufficient power and lifting capacity for demanding commercial-size projects. Maneuverable and very versatile, they can be fitted with many different types of attachments. This size excavator class offers the greatest benefits of use. Popular CAT Models in this class are the CAT 320 and CAT 336.

Large Size (greater than 45 tons)

- These excavators provide massive power and lifting capacity, and are suited for major large-scale projects. Designed to move large volumes of soil and other materials, these excavators can be challenging to transport due to the need of disassembling portions of the machine so that the main excavator components can be loaded onto transport trailers. Although transportation to and from job sites can be a challenge, if you need to handle large volumes of soil the extra investment can be worth the cost. Popular CAT Model in this class is the CAT 349.

CAT Popular Model and Excavator Size Breakdown

- CAT 320 – 22.4 tons

- CAT 336 – 36.5 tons

- CAT 349 – 46.9 tons

Primary Industries Where Excavators are Used

Most, if not all excavator uses can be found in the following industries:

- Agriculture

- Mining

- Construction

- Marine

- Forestry

- Oil and Gas

Optimize Your Excavator.

How HAWK Excavator Can Help

Considering all of the challenges a construction company faces daily, from project to project, it is critical that your operation be outfitted with the best excavation equipment available.

HAWK Excavator is a Manufacturer of Long Reach Excavator Kits, RTK GPS Position Systems, Amphibious Undercarriages, and Modular Barges. We have decades of experience with heavy-duty excavator equipment to enhance and optimize excavation projects worldwide.

Top Product Upgrades for Excavators

- Long Reach Excavator Kits (Stick & Boom)

- HAWK Vision RTK GPS Positioning Systems

- Amphibious Undercarriages

- Sectional Barges

All HAWK products are simple to install to your excavator to assist with a wide range of excavation, construction, and dredging projects.

The top requested product is a conversion from standard to long reach.

For more on the value that HAWK Excavator can provide, Go To: https://hawkexcavator.com/

Articles and Education

Read through our resource library for informational articles that may help you in selecting the right HAWK equipment for the job.