Excavator Types 101

Top 11 Types of Excavators and Their Uses

This Article Includes

- What is an Excavator Used For?

- Top 11 Most Common Excavator Types

- What are the Different Types of Excavation

What is an Excavator Used For?

Excavators are heavy construction equipment that are used for many tasks and functions including digging and material handling, mining, river dredging, construction, forestry, demolition, and any other jobs that require the digging and moving of soil and other types of materials.

Excavators are the workhouse of industry and one of the most common pieces of heavy equipment on construction sites around the globe. Popular manufacturers in this business include CAT, Volvo and Komatsu. These machines are a incredibly versatile technology and can be operated in many different types of environments ranging from the typical construction site, to environments that require the scaling of extremely steep slopes and hillsides.

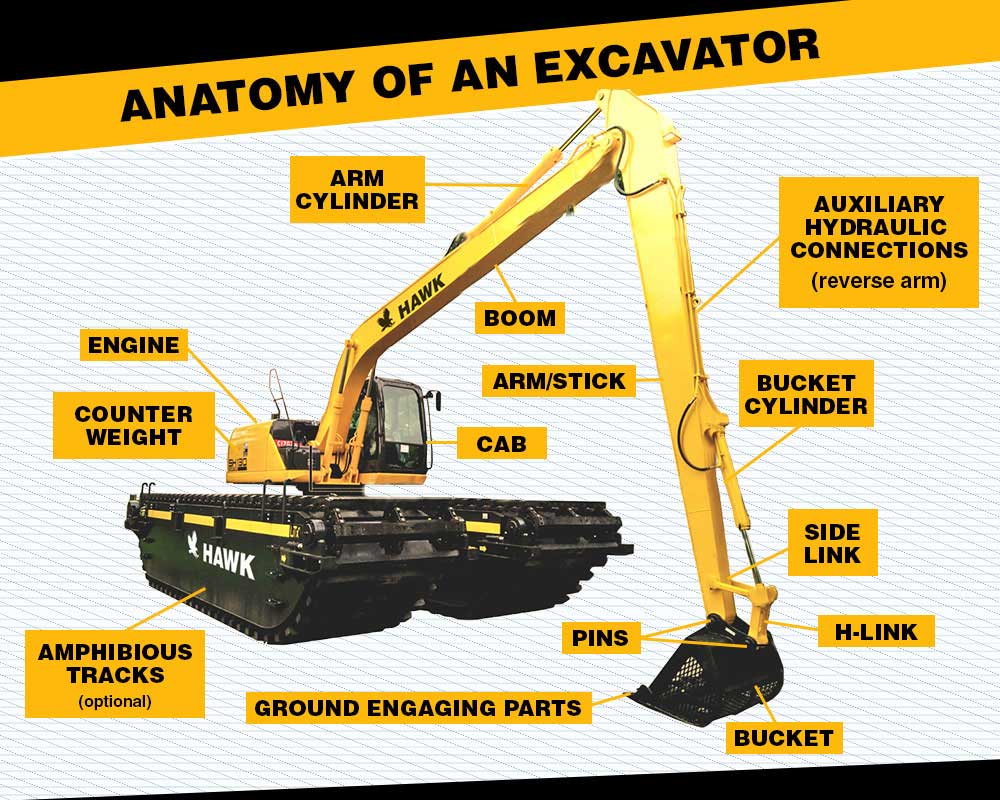

Large excavators (as well as mini excavators) are designed with either wheels or tracks that allow the machine to move across a jobsite. They are also constructed with a boom and stick assembly that can be affixed with many different types of attachments that can perform many tasks. Even the largest excavator will benefit from these attachments. Excavator attachments include buckets, shears for demolition, augers for drilling holes, breaker hammers, rippers, and dredge pumps.

Different types of couplers are also used for quickly switching attachments when the excavator is used for different tasks. Hydraulic excavators tend to benefit most from these attachments, as these high operating weight models tend to have more net power overall and can benefit more from many more configurations when compared to compact excavators.

Most excavators (especially tracked excavators) use a hydraulic system to power the movement of the boom/stick/bucket assembly to perform the specific jobs required such as digging, trenching, debris removal, demolition, dredging, and many other tasks. The hydraulic system is powered by the diesel motor, but when a larger quantity of power is required, a separate Hydraulic Power Unit (HPU) can be used. An HPU can be a stand-alone unit or be affixed to the backside of the excavator.

These machines are available in four sizes: mini excavators (less than 7 tons), mid-size (7 to 10 tons), standard size (10 to 45 tons), and large size (greater than 45 ton operating weight).

Excavators are critical in many industries and vary in type and build depending on what specific uses they are expected to perform.

Top 11 of the Most Common Excavator Types

1. Standard or Crawler Excavator

Standard excavator models are the most popular excavators used because they are designed for the bulk of excavation jobs. They are available in sizes ranging from mini-excavators to large heavy-duty models. These excavators include a boom/stick combination, and a bucket attached to the end of the stick. These excavators run on two tracks that allow the operating weight of the excavator to be distributed more evenly and not be concentrated in one specific area during a dig. This makes this type of excavator more suited for working on soft terrain. They also have a cab assembly that can rotate 360 degrees. Digging and lifting of materials is accomplished by the boom/stick/bucket hydraulic assembly retracting and extending. Buckets are available in various sizes to accommodate many different types of tasks from digging, demolition, dredging and many others. These excavators are ideally suited for mining construction, forestry, farming, and any other industries that require the use of this type of high quality machinery.

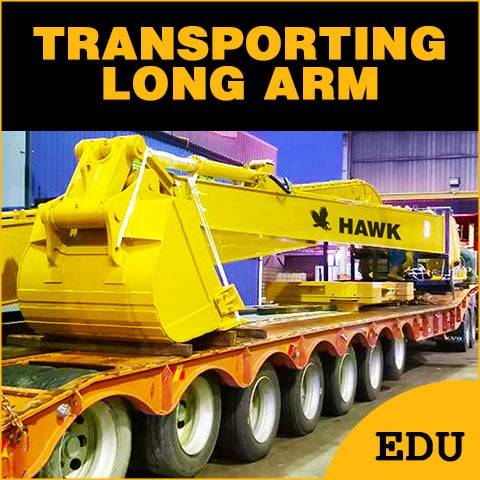

2. Long Reach Excavator

There are a number of variations to the standard excavator (also called a “digger”) and the long reach excavator is one of them. These can be either wheeled or tracked and allow the excavator to have an increased ability to reach further distances, dig more under those conditions, as well as do jobs and work in settings that other types of compact excavators cannot. These details do matter. Some of the jobs they are ideally suited for are dredging in water, industrial demolition, large digging projects, and any task where a standard boom/stick assembly is not efficient or practical. Standard reach excavators have a reach up to 40 feet, and long reach can extend the reach up to 100 feet; long reach has the reaching capability of 2X times greater than standard reach. Financing these long reach attachments is typically quite simple at Hawk. We offer truly flexible, low interest financing options for most models.

3. Wheeled Excavator

Another variation of the standard excavator is the wheeled excavator, which tend to have a lower operating weight. Although these models can achieve the same tasks as the standard track excavator (with greatly reduced tailswing), it is better suited for situations where the excavator must operate on hard surfaces such as concrete and asphalt. Wheeled excavator models are easier to maneuver and can move about a jobsite at faster speeds. Although these models tend to be of lower capacity, the maneuverability can be a big time saver and increase the potential of completing jobs in a shorter period of time. A wheeled excavator with a lower operating weight (and capacity) can be driven on city streets, which allows it to be driven to a jobsite.

4. Backhoe Excavator

Backhoe excavators can perform multiple tasks without having to switch out boom attachments as often because this type of excavator is designed with a boom/stick/bucket assembly on one end, and a bucket to dig with on the other. Able to accomplish the same tasks as a standard, lower capacity excavator, the backhoe excavator is a more versatile technology than standard models because of the bucket located at the front of the machine. They are capable of moving larger volumes of materials than standard machines, and can be fitted with many more attachments. They are ideally suited for landscaping, mining, construction, loading and unloading materials and debris and many other types of uses.

5. Hydraulic Shovels

Hydraulic shovels are heavy-duty and designed for very extreme lifting and digging jobs. They are typically found in mining jobs and have much larger lifting arms and buckets than do standard and other types of large excavators. They can dig with incredible net power, as well as haul large rocks, soil, and other materials that are too heavy for other types of machines. These machines are high capacity, tend to have a large operating weight and offer serious uptime. Hydraulic shovels are similar to standard models in that they have a boom/stick/bucket assembly located at the front of the excavator, but they can also be affixed at the back of the excavator. They also have a cab assembly that can rotate 360 degrees which is consistent with most other types of excavators.

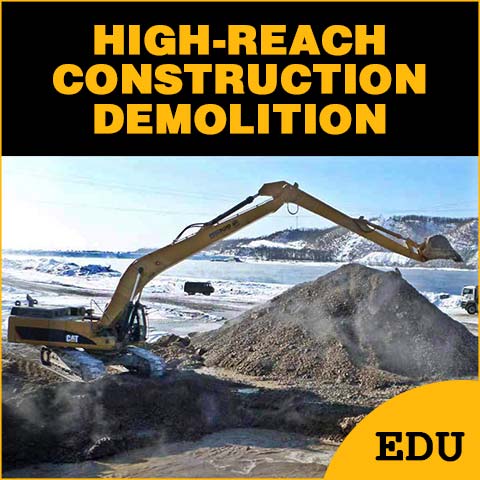

6. Demolition Excavator

Demolition excavators are used for the demolition of industrial structures, buildings, and any other structure that requires dismantling. They are built with special guards that cover the cab and windows of the cab to protect the operator from falling debris resulting from the demolition work that is being performed. Demolition excavators are also fitted with heady duty undercarriages to withstand the harsh environment that these excavators operate. Shearing attachments are commonly used on this type of excavator for shearing metal girders, and other materials that must be cut into pieces as part of the demolition process.

7. Vacuum Truck or Suction Excavator

Vacuum trucks are used in situations that require precision removal of material without damaging surrounding cables and piping that can be located under or overground. They are constructed with high-pressure vacuum and water jets that are used to loosen and precisely draw material into the vacuum piping and into the holding tank located on the vacuum truck. These machines offer greater safety and a lower operating weight in comparison to other types of excavators.

8. Skid Steer Excavator

These often lower capacity models are designed with the boom/stick/bucket assembly facing away from the operator; this orientation is opposite of a standard excavator. Very common at construction sites, they are used for cleaning debris from job sites, digging pools, and useful in work areas where space is limited but the materials to be moved are located at further distances. They are also more maneuverable than other types of excavators and are capable of overcoming challenging turning conditions when manueverability.

9. Spider or Walking Excavator

Spider excavators are one of the most unique and impressive-looking types of excavators and are designed with spider-like legs that can operate independently. This unique excavator is designed for specialized situations that require the excavator to maneuver on extremely steep hillsides and the most challenging terrains. The legs can be fixed or telescoping so that the wheels at each end of the legs can be located on secure footing whether it be angular sides of gullies, cliff ledges, or anywhere else solid footing is required to allow for safe and effective excavation.

These are very special machines and considered the mountain goats of the machine world. Consistent with other types of excavators, the cab sits on a rotating platform that can rotate 360 degrees, and the boom/stick/bucket assembly is located at the front of the excavator. Not seen at many construction sites, they are ideal for forestry due to the steep cliff faces and challenging terrain.

10. Knuckle Boom Excavator

The knuckle boom excavator is another variation of the standard excavator but is designed with an extra joint on the boom/stick assembly. This extra knuckle allows the stick and bucket to rotate from side to side, which increases maneuverability for working in tight spaces and excavating around obstacles. Although the knuckle excavator is one of the least commonly used excavators, it can be greatly beneficial in the right situations.

11. Amphibious Excavator

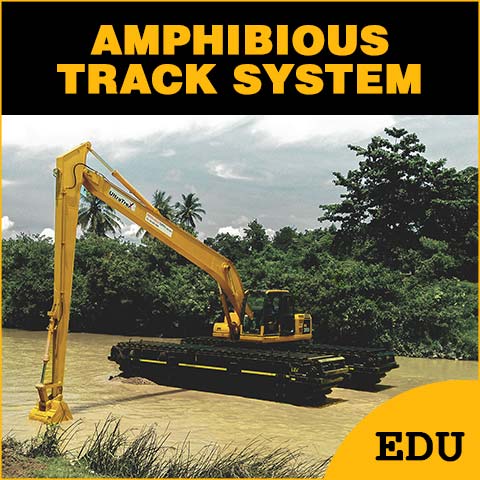

Amphibious excavators are another one of the specialized excavator types and are used for sediments and debris that can be located at the bottom of bodies of water such as lakes, harbors, rivers, ponds, and other types of waterways. Over a period of time sedimentation begins to fill harbors, and rivers that can interfere with the passage of cargo vessels that are being used to transport materials and goods. Amphibious excavators are used to performing a function called dredging that, essentially, is the removal and transport of this sediment to a location away from the existing waterway. They are also used for control of vegetation and installing underwater cables and piping. These excavators are uniquely designed with an amphibious undercarriage, sealed pontoons, and a buoyancy tank which allows the excavator to float on the surface of the waterway. Also included in the design of this excavator are main hydraulic pumps with traveling motors to help propel the amphibious excavator through the water.

What are the Different Types of Excavation?

Topsoil Excavation

With most types of construction projects, removal of the topsoil is a critical part of the process of preparing a stable and solid foundation for the building and construction process to take place. Prior to the process of removing the topsoil, the area that is to be excavated is marked with the use of a process called ground tracing. Ground tracing identifies the specific area that the excavation will occur. Along with ground tracing, a specific depth of soil removal will be indicated. Once this part of the process is complete an excavator will be used to begin removing the topsoil and relocating it to another desired location.

Rock Excavation

When excavating some areas the soil can be rocky and contain large boulders or large fragments. When this is the case, the larger boulders and rock fragments must be removed by either mechanical means or introducing explosives to break the large boulders into smaller rock fragments. Rock excavation is the removal and extraction of isolated boulders and rock fragments that are in excess of 1-cubic yard. Due to the involvement of explosives and heavy duty excavation equipment rock excavation is very dangerous, and can be one of the most risky types of excavation.

Footing Excavation

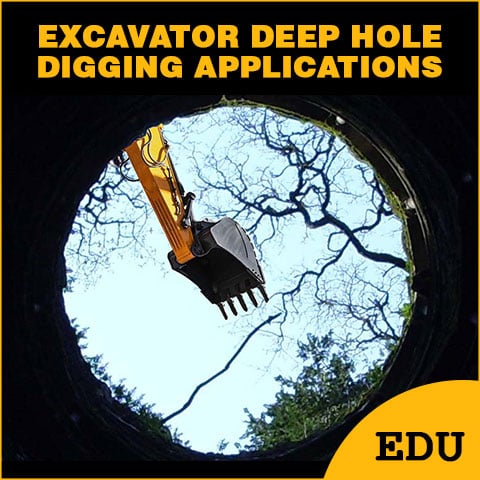

Prior to beginning construction on any buildings, bridges, and any other structures footings are formed to make sure the building has a strong and stable foundation. This is done to ensure that the structure does not sink or collapse. Sinking or collapsing can occur due to such things as settlement of the structure over a period of time, as well as freezing and thawing that can occur in the colder months of the year. Before a footing can be constructed, footing execution is executed which consists of digging a continuous trench that is usually between 4-ft. and 10-ft. in depth. Footer depths can be as deep as 15-ft. or deeper, especially in cold climate areas where the footer depth extends below the frost line.

Earth Excavation

This type of excavation involves the removal of the layer of soil just beneath the topsoil which is called spoil (soil, dirt, rubble). Once spoil is removed it is typically used for constructing embankments and foundations. This layer of soil is also excavated to allow for the constructing buildings, bridges, and drainage ditches.

Cut and Fill Excavation

This type of excavation is where the toil soil, and sometimes the next depth of soil below the topsoil is cut and stripped, and used as fill for making embankments and elevated sections. The material that is extracted in this type of excavation is also used as filler for constructing foundations of buildings.

Trench Excavation

Trench excavation is similar to footing excavation except that trench excavation can be done for a wider range of reasons than creating a footing for a structure. As an example trenches can be dug for pipelines and sewers. Trenches that are less than 19-ft. Deep are considered shallow, and trenches that are 19-ft. or greater are considered deep. When excavating trenches, the process is conducted in phases to safeguard against the collapse of the trench.

Dredge Excavation

Dredging is a crucial form of excavation that involves the removal of sediment and debris that collects over a period of time from the bottom of lakes, channels, harbors, rivers, ponds, and any other bodies of water where sediments collect at the bottom. Sedimentation consists of sand and silt and when it collects and build-up occurs it restricts the path of boats, ships, and other water vehicles that transverse the waterways. Sediment and debris is removed on a periodic basis to restore the restricted waterways, allowing boats and ships an unobstructed voyage to the destination.

Optimize Your Excavator.

How HAWK Excavator Can Help

Considering all of the challenges a construction company faces daily, from project to project, it is critical that your operation be outfitted with the best excavation equipment available.

HAWK Excavator is a Manufacturer of Long Reach Excavator Kits, RTK GPS Position Systems, Amphibious Undercarriages, and Modular Barges. We have decades of experience with heavy-duty excavator equipment to enhance and optimize excavation projects worldwide.

Top Product Upgrades for Excavators

- Long Reach Excavator Kits (Stick & Boom)

- HAWK Vision RTK GPS Positioning Systems

- Amphibious Undercarriages

- Sectional Barges

All HAWK products are simple to install to your excavator to assist with a wide range of excavation, construction, and dredging projects.

The top requested product is a conversion from standard to long reach.

For more on the value that HAWK Excavator can provide, Go To: https://hawkexcavator.com/

Articles and Education

Read through our resource library for informational articles that may help you in selecting the right HAWK equipment for the job.