Home /

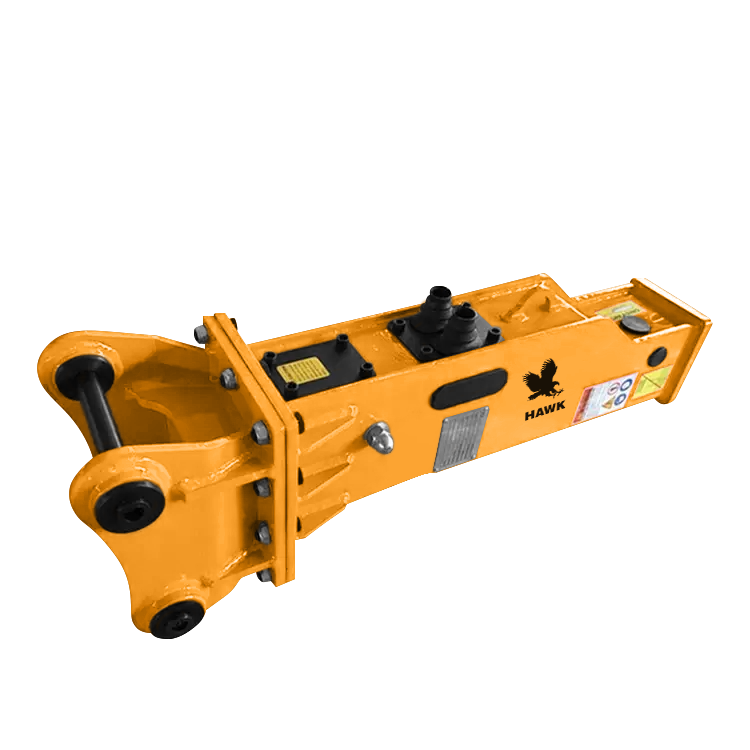

Hydraulic Breaker Hammer – HBH1250B

HAWK’s hydraulic breaker hammer – HBH1250B (BOX) is essential in mining, demolitions, excavations, and quarries as it chips away large boulders and concrete structures. Most contractors prefer using the hydraulic hammer breaker because of its high performance, and it is also why it is present on most construction sites. The brand’s hydraulic hammer rock breaker reduces manual work, relatively saves energy, and stands to its efficient but straightforward working principle.

HAWK is also a preferred brand for its quality and versatility.

The HAWK Hydraulic Breaker Hammer Box – HBH1250B is part of the Hydraulic Breaker Hammer BOX Series, which offer a variety of other diameters, tonnages, working flow and working pressures.

Excavator Tonnage: 15-25 Tons

Kinds: Box

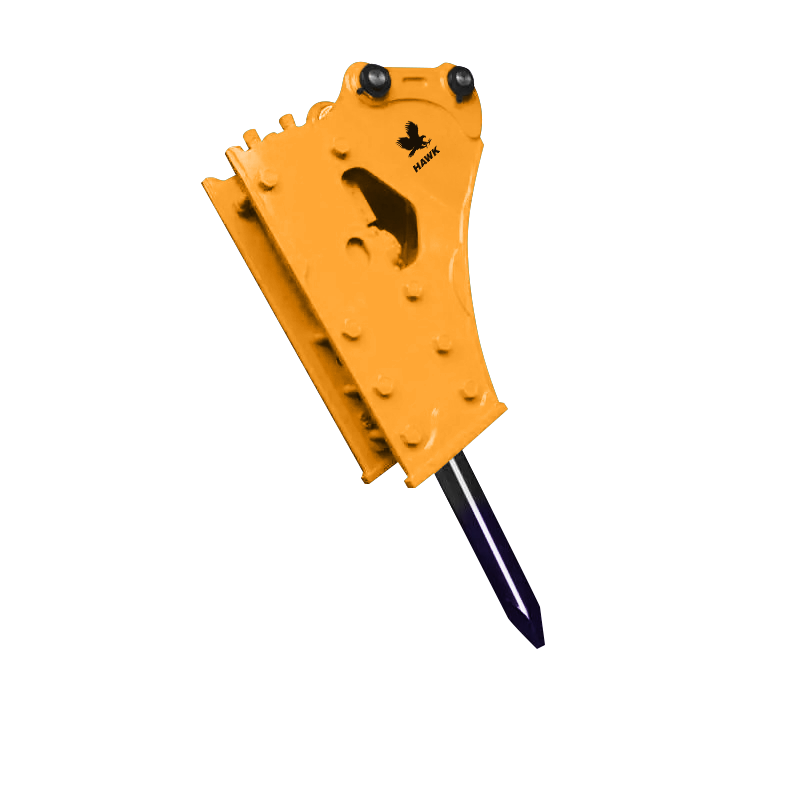

Kinds of chisels: Moil point, Blunt, Flat chisel, Conical point

Chisel Quantity: 2

Work condition: Break up concrete, rock, and other hard materials.

Main Features:

1. Easy to locate and control.

2. More conducive to excavate.

3. Weight lighter, the lower risk of broken drill rode.

Applications:

1. Mining

2. Demolition

3. Construction

4. Quarry

Product Specifications

Model: HBH1250B

Excavator Weight: 15-25 Tons

Chisel Diameter: 5 in (125 mm)

Operating Weight: 3351 lbs. (1520 kg)

Working Flow: 24-32 GPM (90-120 L/min)

Working Pressure: 2134-2418 PSI (150-170 kg/cm2)

Can be mounted on the following hydraulic excavators, mini-excavators and other carriers:

1. Skid steer loader

2. Backhoe loader

3. Crane

4. Telescopic handler

5. Wheel loader

By Excavator

A hydraulic hammer, also known as a hydraulic breaker, is a heavy-duty machine used in construction and demolition work to break up hard materials such as concrete, rock, asphalt, and other materials. The hammer is typically mounted on an excavator or other hydraulic machine and is powered by the hydraulic system of the vehicle.

The hydraulic hammer works by using a piston to strike the surface of the material with high impact force, breaking it apart into smaller pieces. The hammer’s chisel or point is placed against the material, and the piston rapidly strikes it, creating a powerful impact that breaks the material. The repeated blows quickly break apart the material, allowing it to be removed or excavated.

Hydraulic hammers are available in a range of sizes and shapes, with different chisel types and lengths, depending on the specific application. They are commonly used in construction, mining, and quarrying operations, as well as in road and bridge repair and demolition work. Hydraulic hammers are designed to be durable and reliable, with a long service life, making them an essential tool for many construction and demolition projects.