Rotating Hydraulic Grapple – RHG400

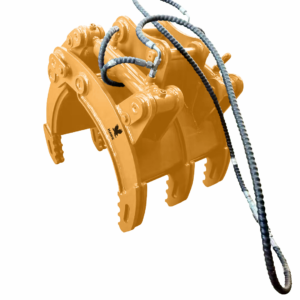

The HAWK Excavator RHG400 rotating hydraulic grapple series stands out as a natural performer in construction and material re-handling tasks and caters to a wide range of operational needs. Its precision grip and high level maneuverability ensure your tasks are completed quickly and effectively.

HAWK’s RHG400 rotating hydraulic grapple is built for Excavators up to 45 tons and is renowned for its efficiency, durability, and quality. Customers can customize their equipment based on various parameters, ensuring optimal performance and operational compatibility.

Excavator Range: 35-45 Ton

Working Conditions: Use in operations like excavation and loading of wood, brick, and loose materials.

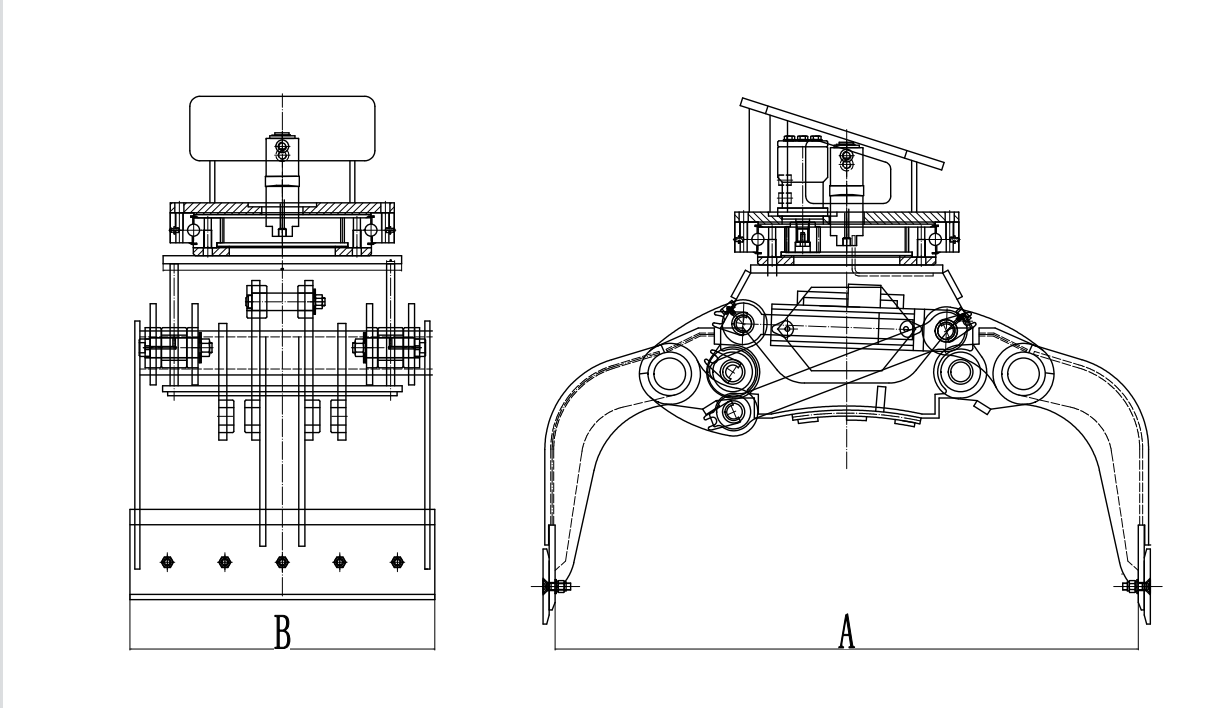

Product Specifications

Model: RHG400

Max Opening: 98.4″ in (2500 mm)

Operating Pressure: 2275 – 2560 psi (160-180 Kg/cm2)

Set Up Pressure: 3555 psi (250 Kg/cm2)

Operating Flux: 52.8 – 66 GPM (200-250 L/Min)

Weight: 4409.2 lbs (2000 kg)

Material: Q355+NM400

Applications:

- Mining

- Demolition

- Construction

- Quarry

- Skid steer loader

- Backhoe loader

- Crane

- Telescopic handler

- Wheel loader

- Excavator

Benefits of Rotating Hydraulic Grapples

Rotating hydraulic grapples provide exceptional functionality and versatility, making them an essential tool for various heavy-duty applications. Here are the key benefits of utilizing rotating hydraulic grapples:

360-Degree Rotation: The continuous 360-degree rotation capability allows for precise positioning and manipulation of materials. This feature enhances maneuverability and efficiency, making it easier to handle materials in confined or complex environments.

Enhanced Versatility: Rotating hydraulic grapples are suitable for a wide range of applications, including demolition, material sorting, waste handling, and forestry. Their ability to rotate provides unmatched flexibility, making them ideal for tasks that require accurate placement and orientation of materials.

Improved Efficiency: The hydraulic rotation mechanism significantly boosts operational efficiency by reducing the time and effort required to reposition materials. This increased efficiency translates to higher productivity and reduced operating costs.

Superior Grip and Control: Equipped with powerful hydraulic cylinders, these grapples offer a strong and secure grip on various materials, ensuring safe and efficient handling. The precise control allows operators to handle delicate or heavy materials with ease, minimizing the risk of damage.

Durable Construction: Rotating hydraulic grapples are constructed from high-strength, wear-resistant materials, ensuring durability and long-term performance even in the toughest working conditions. This robust construction reduces the need for frequent maintenance and replacements.

Increased Safety: The secure gripping mechanism and precise control provided by hydraulic grapples enhance safety on the job site. The ability to rotate materials smoothly reduces the likelihood of accidental drops or mishandling, thereby minimizing potential hazards.

Adaptability to Various Machines: These grapples are compatible with a wide range of excavators and other heavy machinery, making them a versatile addition to any equipment fleet. Their adaptability ensures seamless integration with different types of equipment.

Reduced Operator Fatigue: The hydraulic operation and ease of control reduce the physical strain on operators, leading to less fatigue and higher productivity. This ergonomic benefit is crucial for maintaining operator efficiency over extended periods of use.

Features of Rotating Hydraulic Grapples – RHG400

Rotating hydraulic grapples like the RHG400 are designed to deliver superior performance and versatility in demanding applications. Here are the standout features that make these grapples an indispensable tool for heavy-duty material handling:

360-Degree Continuous Rotation: The grapples feature a robust hydraulic rotator that allows for continuous 360-degree rotation. This enables precise positioning and manipulation of materials from any angle, enhancing operational flexibility and efficiency.

Powerful Hydraulic Cylinders: Equipped with powerful hydraulic cylinders, rotating hydraulic grapples deliver exceptional gripping force. This ensures a secure hold on various materials, from heavy debris to delicate items, improving handling accuracy and safety.

Replaceable Wear Parts: Key components, such as cutting edges and tips, are designed to be easily replaceable. This feature extends the lifespan of the grapple and reduces maintenance downtime, ensuring continuous operation.

Optimized Jaw Design: The jaws are engineered for optimal penetration and gripping capability. The design includes interlocking teeth that provide a firm grip on irregularly shaped materials, enhancing productivity in sorting and handling tasks.

Enhanced Hydraulic System: The advanced hydraulic system includes pressure relief valves and flow control, ensuring smooth and efficient operation. This system is designed to maximize the performance of the grapple while protecting it from hydraulic overload.

Universal Mounting Compatibility: Rotating hydraulic grapples are compatible with a wide range of excavators and other machinery, thanks to their universal mounting system. This versatility allows for easy attachment and detachment, facilitating quick transitions between different machines and tasks.

Protective Hoses and Fittings: The hydraulic hoses and fittings are strategically positioned and shielded to prevent damage during operation. This protective feature minimizes the risk of hydraulic fluid leaks and prolongs the life of the hydraulic components.

Sealed Bearings and Joints: All bearings and joints are sealed to keep out dirt and debris, reducing wear and tear and extending the service life of the grapple. This feature ensures consistent performance in harsh working environments.

Enhanced Operator Visibility: The design of the grapple prioritizes operator visibility, allowing for better control and accuracy during material handling. This ergonomic feature reduces operator fatigue and improves overall safety on the job site.

These features combine to make rotating hydraulic grapples a versatile and reliable attachment for a wide range of material handling applications, from demolition and construction to waste management and recycling. Their robust design, powerful performance, and ease of use make them a valuable addition to any heavy equipment fleet.

Frequently Asked Questions – Rotating Hydraulic Grapple RHG400