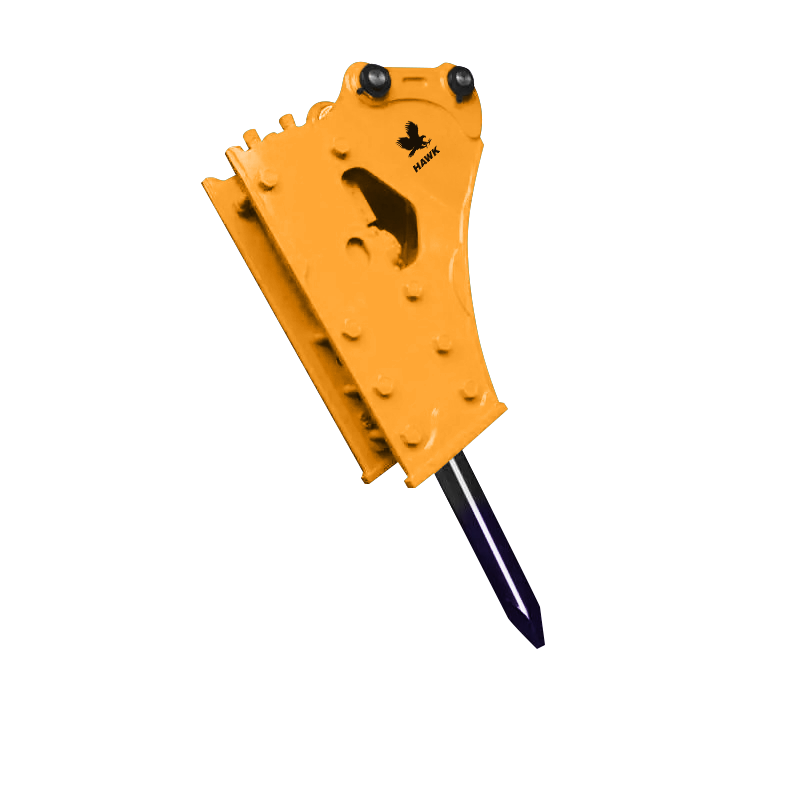

Side Hydraulic Breaker Hammers

HAWK Excavator Side Hydraulic Breaker Hammers are essential in mining, demolitions, excavations, and quarries as they chip away large boulders and concrete structures. Most contractors prefer using the hydraulic hammers because of its high performance, which is also why it is present on most construction sites. The HAWK side hydraulic breaker hammer reduces manual work, saves energy, and stands to its efficient but straightforward working principle.

Side breaker hammers by HAWK Excavator are versatile and combine superior efficiency and high reliability on the job site. They are adaptable and sustainable, fitting every construction need. We offer different sizes of side hydraulic breaker hammers to fit a variety of excavator makes and models. Our breaker hammer designs provide simplicity but adept technology that guarantees ease of setup and premium service support. With this, you will have an extra reliable hand on the job site, helping you in your everyday construction operations.

HAWK is also a preferred brand for its quality and versatility.

Excavator Tonnage: 1-45 Ton

Type: Side

Type of Chisels: Moil point, Blunt, Flat chisel, Conical point

Chisel Quantity: 2

Applications: Break up concrete, rock, and other hard materials.

Product Specifications

| Model | Excavator Weight | Chisel Diameter | Operating Weight | Working Flow | Working Pressure |

|---|---|---|---|---|---|

| Tonnage | Inch (mm) | Lbs (Kgs) | GPM (L/min) | PSI (kg/cm2) | |

| HBH750S | 6-9 Tons | 3 in (75 mm) | 882 lbs. (400 kg) | 13-24 GPM (50-90 L/min) | 1707-2418 PSI (120-170 kg/cm2) |

| HBH850S | 7-14 Tons | 3.5 in (85 mm) | 1213 lbs. (550 kg) | 12-23 GPM (45-85 L/min) | 1806-2090 PSI (127-147 kg/cm2) |

| HBH1000S | 10-15 Tons | 4 in (100 mm) | 1808 lbs (820 kg) | 21-32 GPM (80-120 L/min) | 2134-2418 PSI (150-170 kg/cm2) |

| HBH1250S | 15-25 Tons | 5 in (125 mm) | 3351 lbs (1520 kg) | 24-32 GPM (90-120 L/min) | 2134-2418 PSI (150-170 kg/cm2) |

| HBH1400S | 20-30 Tons | 5.5 in (140 mm) | 3836 lbs (1740 kg) | 40-50 GPM (150-190 L/min) | 2347-2631 PSI (165-185 kg/cm2) |

| HBH1500S | 25-36 Tons | 6 in (150 mm) | 5732 lbs. (2600 kg) | 40-60 GPM (150-230 L/min) | 2418-2845 PSI (170-200 kg/cm2) |

| HBH1650S | 30-45 Tons | 6.5 in (165 mm) | 6834 lbs. (3100 kg) | 53-69 GPM (200-260 L/min) | 2560-2845 PSI (180-200 kg/cm2) |

Hydraulic Breaker Hammer By Excavator

| Manufacturer | Model | Chisel Diameter | Operating Weight | Working Flow | Working Pressure |

|---|---|---|---|---|---|

| Inch (mm) | Lbs (Kgs) | GPM (L/min) | PSI (kg/cm2) | ||

| CASE | CX210 | 5 in (125 mm) | 3351 lbs (1520 kg) | 24-32 GPM (90-120 L/min | 2134-2418 PSI (150-170 kg/cm2) |

| CASE | CX210 | 5.5 in (140 mm) | 3836 lbs (1740 kg) | 40-50 GPM (150-190 L/min) | 2347-2631 PSI (165-185 kg/cm2) |

| Caterpillar | 320 | 5 in (125 mm) | 3351 lbs (1520 kg) | 24-32 GPM (90-120 L/min) | 2134-2418 PSI (150-170 kg/cm2) |

| Caterpillar | 320 | 5.5 in (140 mm) | 3836 lbs (1740 kg) | 40-50 GPM (150-190 L/min) | 2347-2631 PSI (165-185 kg/cm2) |

| Caterpillar | 325 | 5 in (125 mm) | 3351 lbs (1520 kg) | 24-32 GPM (90-120 L/min) | 2134-2418 PSI (150-170 kg/cm2) |

| Caterpillar | 325 | 5.5 in (140 mm) | 3836 lbs (1740 kg) | 40-50 GPM (150-190 L/min) | 2347-2631 PSI (165-185 kg/cm2) |

| Caterpillar | 325 | 6 in (150 mm) | 5732 lbs. (2600 kg) | 40-50 GPM (150-190 L/min) | 2418-2845 PSI (170-200 kg/cm2) |

| Caterpillar | 336 | 6 in (150 mm) | 5732 lbs. (2600 kg) | 40-50 GPM (150-190 L/min) | 2418-2845 PSI (170-200 kg/cm2) |

| Caterpillar | 336 | 6.5 in (165 mm) | 6834 lbs. (3100 kg) | 53-69 GPM (200-260 L/min) | 2560-2845 PSI (180-200 kg/cm2) |

| Caterpillar | 349 | 7 in (178 mm) | 9154 lbs. (4152 kg) | 74-92 GPM (280-348 L/min) | 2760-3044 PSI (194-214kg/cm2) |

| HITACHI | EX120 | 3.5 in (85 mm) | 1213 lbs. (550 kg) | 12-23 GPM (45-85 L/min) | 1806-2090 PSI (127-147 kg/cm2) |

| HITACHI | EX120 | 4 in (100 mm) | 1808 lbs (820 kg) | 21-32 GPM (80-120 L/min) | 2134-2418 PSI (150-170 kg/cm2) |

| John Deere | 200G | 5 in (125 mm) | 3351 lbs (1520 kg) | 24-32 GPM (90-120 L/min) | 2134-2418 PSI (150-170 kg/cm2) |

| John Deere | 200G | 5.5 in (140 mm) | 3836 lbs (1740 kg) | 40-50 GPM (150-190 L/min) | 2347-2631 PSI (165-185 kg/cm2) |

| John Deere | 210G | 5 in (125 mm) | 3351 lbs (1520 kg) | 24-32 GPM (90-120 L/min) | 2134-2418 PSI (150-170 kg/cm2) |

| John Deere | 210G | 5.5 in (140 mm) | 3836 lbs (1740 kg) | 40-50 GPM (150-190 L/min) | 2347-2631 PSI (165-185 kg/cm2) |

| John Deere | 245G | 5 in (125 mm) | 3351 lbs (1520 kg) | 24-32 GPM (90-120 L/min) | 2134-2418 PSI (150-170 kg/cm2) |

| John Deere | 245G | 5.5 in (140 mm) | 3836 lbs (1740 kg) | 40-50 GPM (150-190 L/min) | 2347-2631 PSI (165-185 kg/cm2) |

| John Deere | 350G | 6 in (150 mm) | 5732 lbs. (2600 kg) | 40-50 GPM (150-190 L/min) | 2418-2845 PSI (170-200 kg/cm2) |

| John Deere | 350G | 6.5 in (165 mm) | 6834 lbs. (3100 kg) | 53-69 GPM (200-260 L/min) | 2560-2845 PSI (180-200 kg/cm2) |

| John Deere | 470G | 7 in (178 mm) | 9154 lbs. (4152 kg) | 74-92 GPM (280-348 L/min) | 2760-3044 PSI (194-214kg/cm2) |

| Komatsu | PC210 | 5 in (125 mm) | 3351 lbs (1520 kg) | 24-32 GPM (90-120 L/min) | 2134-2418 PSI (150-170 kg/cm2) |

| Komatsu | PC210 | 5.5 in (140 mm) | 3836 lbs (1740 kg) | 40-50 GPM (150-190 L/min) | 2347-2631 PSI (165-185 kg/cm2) |

| Komatsu | PC360 | 6 in (150 mm) | 5732 lbs. (2600 kg) | 40-50 GPM (150-190 L/min) | 2418-2845 PSI (170-200 kg/cm2) |

| Komatsu | PC360 | 6.5 in (165 mm) | 6834 lbs. (3100 kg) | 53-69 GPM (200-260 L/min) | 2560-2845 PSI (180-200 kg/cm2) |

| Komatsu | PC360 | 7 in (178 mm) | 9154 lbs. (4152 kg) | 74-92 GPM (280-348 L/min) | 2760-3044 PSI (194-214kg/cm2) |

| Volvo | EC480 | 7 in (178 mm) | 9154 lbs. (4152 kg) | 74-92 GPM (280-348 L/min) | 2760-3044 PSI (194-214kg/cm2) |

| Volvo | EC950 | 7.75 in (195 mm) | 10,362 lbs (4700 kg) | 74-92 GPM (280-360 L/min) | 2275-3271 PSI (160-230 kg/cm2) |

| Volvo | EC950 | 8.25 in (210 mm) | 13,558 lbs (6150 kg) | 80-120 GPM (300-450 L/min) | 2987-3556 PSI (210-250 kg/cm2) |

Benefits of Side Hydraulic Breaker Hammers

Side hydraulic breaker hammers offer several benefits for construction, demolition, and mining applications. These benefits include:

Increased productivity: HAWK Excavator hydraulic breaker hammers deliver powerful impacts, allowing for efficiently breaking rock, concrete, and other materials. This increases productivity by reducing the time and effort required to complete the job.

Extremely Versatile: Hydraulic side breaker hammers can be used in various applications, such as demolition, excavation, trenching, and breaking oversized materials. These side breaker hammers by HAWK can also be mounted on different carriers, including excavators, backhoes, and skid steer loaders, providing flexibility to handle various tasks.

Low maintenance: Side hydraulic breaker hammers are designed with minimal moving parts, which reduces the risk of mechanical failures and the need for frequent maintenance. The hydraulic system also eliminates the need for a separate compressor or hoses, simplifying the setup.

Low Noise: HAWK Hydraulic side breaker hammer produces less noise than pneumatic or mechanical hammers. This makes them more suitable for use in urban areas or environments where noise pollution is a concern.

Vibration control: Hydraulic breaker hammers often feature advanced vibration control systems, which minimize the vibration transmitted to the carrier and operator. This reduces fatigue and improves operator comfort, ultimately enhancing productivity.

Heavy-duty Durability: High-quality hydraulic breaker hammers are built with robust materials and components, ensuring a long service life even in challenging working conditions.

Energy efficiency: Side Hydraulic breaker hammers use the hydraulic power of the carrier, which is generally more energy-efficient than pneumatic or mechanical systems. This results in lower fuel consumption and reduced emissions.

Easy attachment: Side Hydraulic breaker hammers can be easily attached to and detached from the carrier, making it convenient for operators to switch between different tools and tasks.

Features of Side Hydraulic Breaker Hammers

Side hydraulic breaker hammers have various features that enhance their performance, durability, and ease of use. Some of these features include:

High-impact energy: HAWK Excavator’s side hydraulic breaker hammers are designed to deliver powerful impacts, enabling them to break through rigid materials such as rock, concrete, and asphalt more efficiently.

Advanced vibration control: The HAWK side breaker hammers incorporate vibration-dampening systems that reduce the vibration transmitted to the carrier and the operator. This helps to minimize fatigue, enhance operator comfort, and improve productivity.

Robust construction: Our high-quality side hydraulic breaker hammers are made from durable materials and components to withstand challenging working conditions and provide a long service life.

Variable frequency and energy control: Adjustable impact frequency and settings of these side breaker hammers allow operators to customize the breaker’s performance for different materials and applications.

Noise reduction: Side hydraulic breakers by HAWK Excavator are designed to minimize noise levels during operation, making them more suitable for use in urban areas or environments where noise pollution is a concern.

Frequently Asked Questions

What is a side-mounted hydraulic breaker hammer, and how does it differ from other types?

A side-mounted hydraulic breaker hammer is an easy to use demolition attachment mounted on the side of heavy equipment, such as excavators or backhoes, rather than on the front. Unlike traditional front-mounted breakers, side-mounted breakers provide greater flexibility and maneuverability, especially in tight or confined spaces.

What are the main advantages of using side-mounted hydraulic breaker hammers?

Side-mounted hydraulic breaker hammers offer several benefits, including improved visibility for the operator, more accessible access to confined areas, enhanced stability during operation, reduced stress on the carrier machine, and increased versatility in tackling various demolition tasks.

How do I know if a side-mounted hydraulic breaker hammer is compatible with my equipment?

Compatibility depends on factors such as the weight and size of the hydraulic breaker, the hydraulic flow and pressure requirements, and the mounting configuration of the carrier machine. It’s essential to consult with a heavy equipment expert or the manufacturer to ensure proper compatibility and safe operation.

What types of applications are side-mounted hydraulic breaker hammers suitable for?

Side mounted hydraulic breaker hammers are versatile tools that can be used for a wide range of demolition applications, including breaking up concrete and asphalt, trenching, rock excavation, and site preparation. Their compact design and maneuverability make them particularly well-suited for urban construction projects and tight job sites.

How do I install and operate a side-mounted hydraulic breaker hammer safely?

Proper installation and operation of a side-mounted hydraulic breaker hammer are critical for safety and performance. Follow the manufacturer’s guidelines and recommendations for mounting the breaker securely to the carrier machine, ensuring all hydraulic connections are tight and secure. Operators should receive thorough training on equipment operation and safety procedures, including proper use of controls, maintenance protocols, and safety precautions to prevent accidents and injuries.